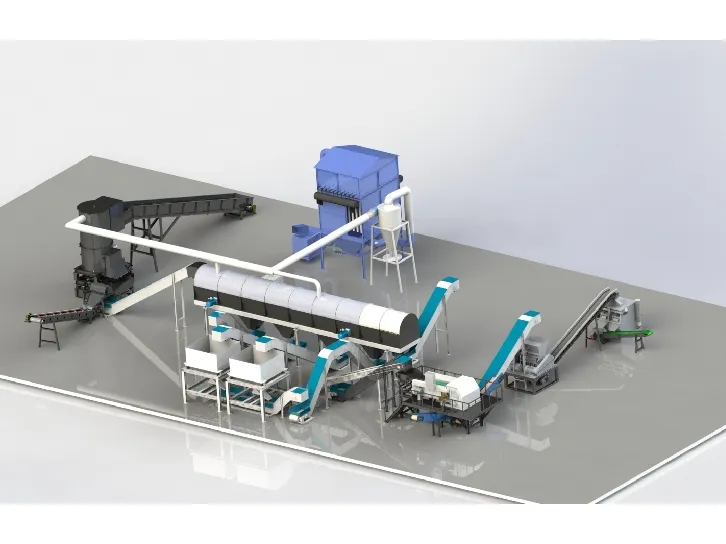

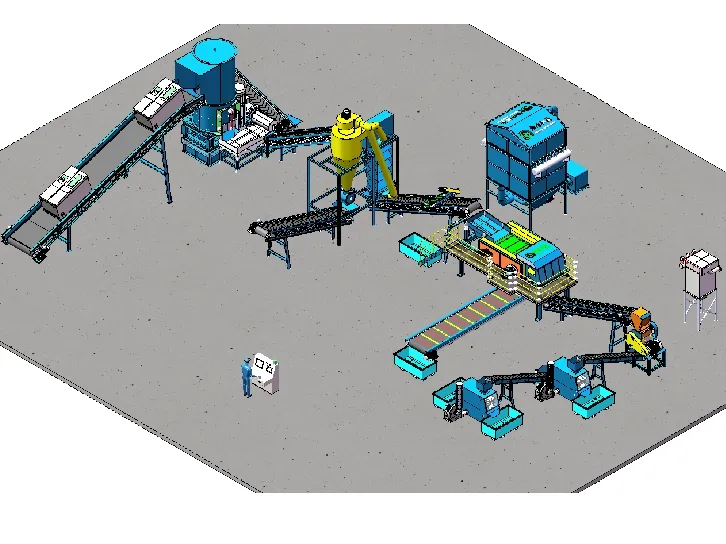

E waste refrigerator recycling plant

E waste refrigerator recycling plantTo achieve effective material processing, the company has adopted German technology, utilizing a chain vertical crusher to crush materials in a single step. This advanced crushing technology ensures the efficient breakdown of the input materials, preparing them for subsequent separation processes. Following the crushing stage, the plant employs a range of equipment, including magnetic separation, dust removal systems, foam collection units, and eddy current separators, to effectively separate and recover valuable materials such as copper, aluminum, plastic, iron, and foam.

The utilization of these advanced separation technologies enables the plant to achieve an impressive recovery rate of over 99%, highlighting its efficiency in extracting valuable resources from e-waste materials. This high recovery rate not only contributes to sustainable resource management but also aligns with environmental conservation efforts by minimizing the amount of waste sent to landfills.

Moreover, the production line is characterized by a high degree of automation and processing efficiency, resulting in significant resource and labor savings. The streamlined and automated processes not only improve work efficiency but also enhance the overall operational productivity of the recycling plant. Additionally, the flexibility to customize assembly lines according to customer requirements allows for tailored solutions that can address specific e-waste processing needs and material compositions.

In conclusion, the e-waste refrigerator recycling plant represents a state-of-the-art facility equipped with advanced technologies for the efficient and sustainable processing of electronic waste. By adopting German technology, implementing advanced material crushing and separation processes, and offering customization options, the plant demonstrates a commitment to resource recovery, environmental responsibility, and operational efficiency in the recycling of e-waste materials.

Application

-Scrap household appliances, such as refrigerators, washing machines, microwaves, etc

-Circuit board and LCD screen

-Electronic and electrical waste

-Combination materials: metal and plastic, iron and non-ferrous metals, aluminum and plastic, wood and glass

-Metal shavings such as aluminum shavings, iron shavings, etc

-Tin plated and aluminum waste cans, such as waste cans, paint cans, spray cans, etc

-Slag

Technical Parameters

Technical Parameters|

Model |

Dimension (L*W*H)mm |

Main shredder diameter (mm) |

Capacity for e waste (kg/h)

|

Capacity for refrigerator (kg/h) |

Main shredder Power(kw) |

|

V100 |

1900*2000*3400 |

1000 |

500-800 |

|

30/45 |

|

V160 |

2840*2430*4900 |

1600 |

1000-3000 |

30-60 |

75/90/130 |

|

V200 |

3700*3100*5000 |

2000 |

4000-8000 |

60-80 |

90/160 |

|

V250 |

4000*3100*5000 |

2500 |

8000-1000 |

80-100 |

250/315 |

Related News

-

Double Shaft Shredder Price Explained: Global Trends, Benefits & Vendor Comparisons

Discover everything about double shaft shredder price, from what affects costs, global industry demand, to vendor comparisons and future trends. Make educated investments for sustainable shredding solutions.

Read More -

Expert Insights into Double Shaft Shredder Factory: Boosting Global Recycling Efficiency

Discover how double shaft shredder factories are revolutionizing waste processing globally with durable, scalable, and cost-effective shredders. Learn benefits, challenges, and future trends.

Read More -

Leading Double Shaft Shredder Suppliers for Industrial Recycling and Waste Management

Discover top double shaft shredder suppliers offering durable and efficient shredding solutions worldwide. Learn product specs, industry insights, and sustainability benefits.

Read More