E egbin firiji atunlo ọgbin

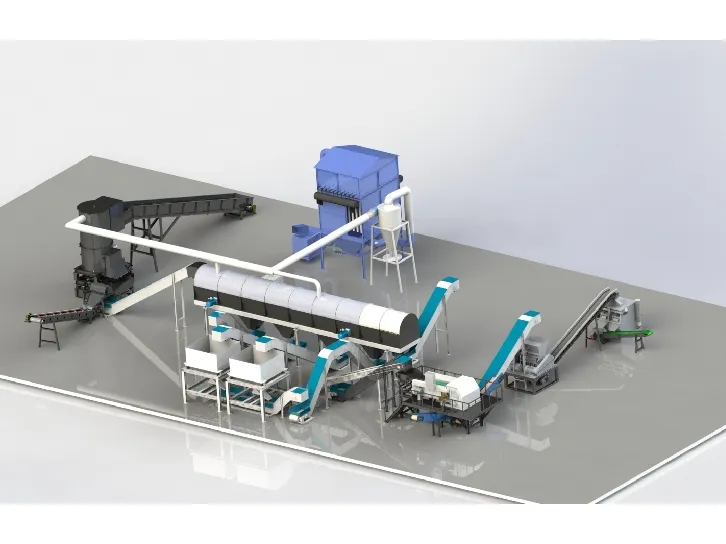

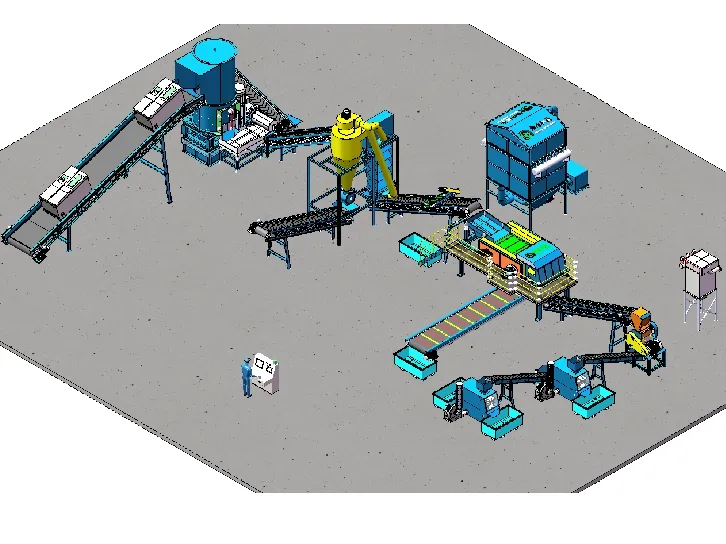

E egbin firiji atunlo ọgbinLati ṣaṣeyọri sisẹ ohun elo ti o munadoko, ile-iṣẹ naa ti gba imọ-ẹrọ Jamani, ni lilo ẹrọ fifọ inaro pq lati fọ awọn ohun elo ni igbesẹ kan. Imọ-ẹrọ fifun ni ilọsiwaju yii ṣe idaniloju idinku daradara ti awọn ohun elo titẹ sii, ngbaradi wọn fun awọn ilana iyapa atẹle. Ni atẹle ipele fifunpa, ọgbin naa nlo ọpọlọpọ awọn ohun elo, pẹlu iyapa oofa, awọn ọna yiyọ eruku, awọn ẹya ikojọpọ foomu, ati awọn iyapa lọwọlọwọ eddy, lati yapa ni imunadoko ati gba awọn ohun elo ti o niyelori pada gẹgẹbi Ejò, aluminiomu, ṣiṣu, irin, ati foomu.

Lilo awọn imọ-ẹrọ iyapa ilọsiwaju wọnyi jẹ ki ọgbin naa ṣaṣeyọri oṣuwọn imularada iwunilori ti o ju 99%, ti n ṣe afihan ṣiṣe rẹ ni yiyo awọn orisun to niyelori lati awọn ohun elo e-egbin. Iwọn imularada giga yii kii ṣe idasi nikan si iṣakoso awọn orisun alagbero ṣugbọn tun ṣe deede pẹlu awọn akitiyan itọju ayika nipa didinku iye egbin ti a fi ranṣẹ si awọn ibi ilẹ.

Pẹlupẹlu, laini iṣelọpọ jẹ ijuwe nipasẹ iwọn giga ti adaṣe ati ṣiṣe ṣiṣe, ti o yọrisi awọn orisun pataki ati awọn ifowopamọ iṣẹ. Awọn ilana ṣiṣanwọle ati adaṣe kii ṣe imudara iṣẹ ṣiṣe nikan ṣugbọn tun mu iṣelọpọ iṣiṣẹ lapapọ ti ọgbin atunlo. Ni afikun, irọrun lati ṣe akanṣe awọn laini apejọ ni ibamu si awọn ibeere alabara ngbanilaaye fun awọn solusan ti a ṣe deede ti o le koju awọn iwulo ṣiṣe e-egbin kan pato ati awọn akopọ ohun elo.

Ni ipari, ile-iṣẹ atunlo firiji e-egbin duro fun ohun elo-ti-ti-aworan ti o ni ipese pẹlu awọn imọ-ẹrọ to ti ni ilọsiwaju fun ṣiṣe daradara ati ṣiṣe alagbero ti egbin itanna. Nipa gbigba imọ-ẹrọ Jamani, imuse awọn ohun elo to ti ni ilọsiwaju fifun pa ati awọn ilana ipinya, ati fifun awọn aṣayan isọdi, ohun ọgbin ṣe afihan ifaramo si imularada awọn orisun, ojuse ayika, ati ṣiṣe ṣiṣe ni atunlo awọn ohun elo e-egbin.

Ohun elo

- Awọn ohun elo inu ile, gẹgẹbi awọn firiji, awọn ẹrọ fifọ, awọn microwaves, ati bẹbẹ lọ

-Circuit ọkọ ati LCD iboju

- Itanna ati itanna egbin

- Awọn ohun elo idapọ: irin ati ṣiṣu, irin ati awọn irin ti kii-ferrous, aluminiomu ati ṣiṣu, igi ati gilasi

-Irun irun bi irin aluminiomu, irun irin, ati bẹbẹ lọ

-Tin palara ati awọn agolo egbin aluminiomu, gẹgẹbi awọn agolo egbin, awọn agolo kikun, awọn agolo sokiri, ati bẹbẹ lọ

-Slag

Imọ paramita

Imọ paramita|

Awoṣe |

Iwọn (L*W*H)mm |

Shredder akọkọ opin (mm) |

Agbara fun e egbin (kg/h)

|

Agbara fun firiji (kg/h) |

Akọkọ shredder Agbara (kw) |

|

V100 |

1900*2000*3400 |

1000 |

500-800 |

|

30/45 |

|

V160 |

2840*2430*4900 |

1600 |

1000-3000 |

30-60 |

75/90/130 |

|

V200 |

3700*3100*5000 |

2000 |

4000-8000 |

60-80 |

90/160 |

|

V250 |

4000*3100*5000 |

2500 |

8000-1000 |

80-100 |

250/315 |

Awọn iroyin ti o jọmọ

-

Troubleshooting Common Eddy Separator Problems

In the realm of recycling and material separation, eddy current separator, eddy separator, and eddy current sorting machine play a vital role in efficiently separating non - ferrous metals from various waste streams.

Ka siwaju -

The Role of Metal Recycling Plants in Circular Economy

In the pursuit of sustainable development, the circular economy has emerged as a crucial concept.

Ka siwaju -

The Impact of Recycling Line Pickers on Waste Management Costs

In the intricate landscape of waste management, every component plays a crucial role in determining operational costs.

Ka siwaju