E litšila sehatsetsi recycled plant

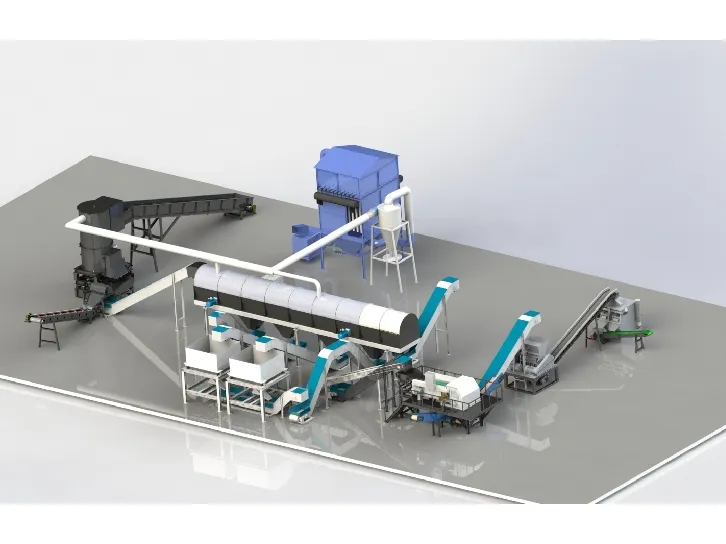

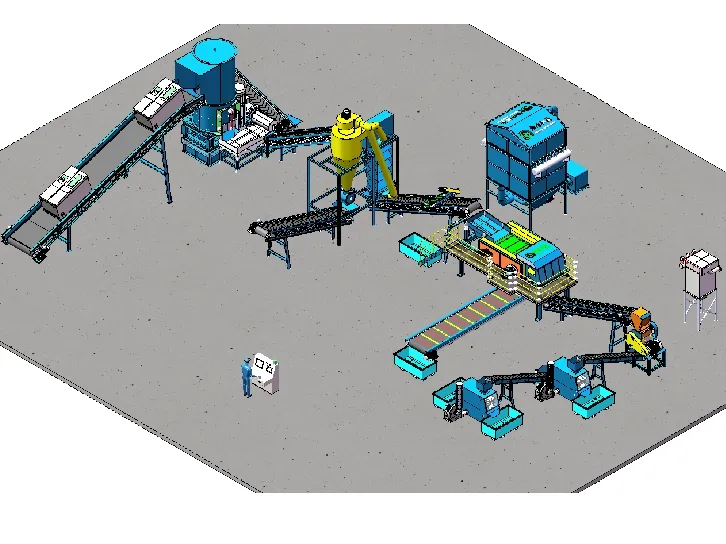

E litšila sehatsetsi recycled plantHo fihlela ts'ebetso e sebetsang ea thepa, k'hamphani e amohetse theknoloji ea Jeremane, e sebelisa mochini o otlolohileng oa ketane ho pshatla lisebelisoa ka mohato o le mong. Theknoloji ena e tsoetseng pele ea ho senya e tiisa ho senyeha ka katleho ha lisebelisoa tsa ho kenya letsoho, ho li lokisetsa bakeng sa mekhoa ea ho arohana e latelang. Ka mor'a sethala sa ho senya, semela se sebelisa lisebelisoa tse ngata, ho kenyelletsa karohano ea matla a khoheli, lisebelisoa tsa ho tlosa lerōle, lihlopha tsa ho bokella foam, le li-separators tsa hona joale tsa eddy, ho arola ka katleho le ho fumana lisebelisoa tsa bohlokoa tse kang koporo, aluminium, polasetiki, tšepe le foam.

Tšebeliso ea mekhoa ena e tsoetseng pele ea karohano e nolofalletsa polante ho fumana sekhahla se tsotehang sa ho hlaphoheloa sa ho feta 99%, e totobatsang bokhoni ba eona ba ho ntša mehloli ea bohlokoa ho thepa ea e-waste. Sekhahla sena se phahameng sa ho hlaphoheloa ha se kenye letsoho feela taolong ea moshoelella ea lisebelisuoa empa hape se ikamahanya le matsapa a paballo ea tikoloho ka ho fokotsa bongata ba litšila tse romeloang litsing tsa lithōle.

Ho feta moo, mohala oa tlhahiso o khetholloa ka tekanyo e phahameng ea ho iketsetsa le ho sebetsa ka katleho, ho fella ka ho boloka mehloli ea bohlokoa le ho boloka basebetsi. Mekhoa e hlophisitsoeng le e ikemetseng ha e ntlafatse bokhoni ba mosebetsi feela empa hape e ntlafatsa tlhahiso ea kakaretso ea polante ea ho tsosolosa. Ho feta moo, ho feto-fetoha ha maemo ho ikamahanya le mela ea kopano ho latela litlhoko tsa bareki ho lumella litharollo tse hlophisitsoeng tse ka sebetsanang le litlhoko tse itseng tsa ts'ebetso ea litšila tsa elektroniki le lipina tsa thepa.

Qetellong, setsi sa ho tsosolosa sehatsetsi sa e-waste se emela setsi sa morao-rao se nang le theknoloji e tsoetseng pele bakeng sa ts'ebetso e sebetsang le e tsitsitseng ea litšila tsa elektronike. Ka ho amohela theknoloji ea Jeremane, ho kenya ts'ebetsong mekhoa e tsoetseng pele ea ho senya le ho arola, le ho fana ka likhetho tsa ho itloaetsa, polante e bontša boitlamo ba ho hlaphoheloa ha lisebelisoa, boikarabelo ba tikoloho, le ts'ebetso ea ts'ebetso ea ts'ebetsong ea lisebelisoa tsa e-waste.

Kopo

- Lahla lisebelisoa tsa ka tlung, joalo ka lihatsetsi, metjhini e hlatsoang, li-microwave, jj

- Boto ea potoloho le skrine ea LCD

- Litšila tsa elektronike le tsa motlakase

- Lisebelisoa tse kopantsoeng: tšepe le polasetiki, tšepe le tšepe e sa fereheng, aluminium le polasetiki, lehong le khalase.

- Metako ea tšepe e kang li-shavings tsa aluminium, li-shavings tsa tšepe, joalo-joalo

- Mekotla e entsoeng ka thini le ea aluminium ea litšila, joalo ka makotikoti a litšila, makotikoti a pente, makotikoti a spray, joalo-joalo.

- Slag

Tekheniki Parameters

Tekheniki Parameters|

Mohlala |

Boemo (L*W*H)mm |

Sehlahisoa se seholo bophara (mm) |

Bokhoni bakeng sa e senya (kg/h)

|

Bokhoni ba sehatsetsi (kg/h) |

Ka sehloohong qhetsola Matla(kw) |

|

V100 |

1900*2000*3400 |

1000 |

500-800 |

|

30/45 |

|

V160 |

2840*2430*4900 |

1600 |

1000-3000 |

30-60 |

75/90/130 |

|

V200 |

3700*3100*5000 |

2000 |

4000-8000 |

60-80 |

90/160 |

|

V250 |

4000*3100*5000 |

2500 |

8000-1000 |

80-100 |

250/315 |

Litaba Tse Amanang

-

Troubleshooting Common Eddy Separator Problems

In the realm of recycling and material separation, eddy current separator, eddy separator, and eddy current sorting machine play a vital role in efficiently separating non - ferrous metals from various waste streams.

Bala haholoanyane -

The Role of Metal Recycling Plants in Circular Economy

In the pursuit of sustainable development, the circular economy has emerged as a crucial concept.

Bala haholoanyane -

The Impact of Recycling Line Pickers on Waste Management Costs

In the intricate landscape of waste management, every component plays a crucial role in determining operational costs.

Bala haholoanyane