Copper wire granulators

Copper wire granulators

Brief introduction

Brief introduction

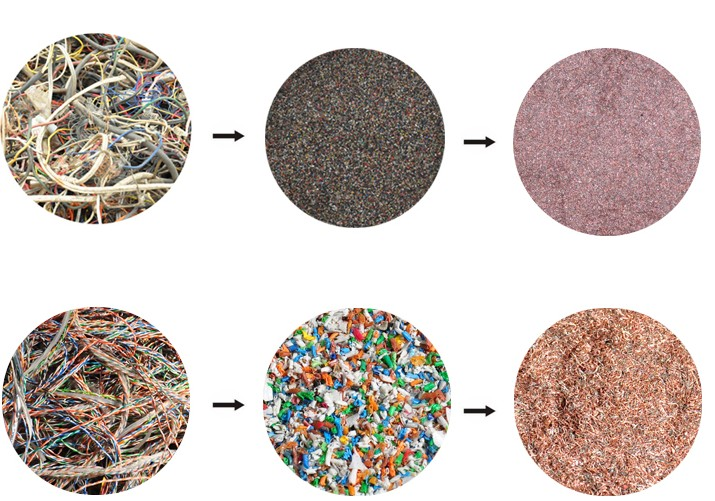

One of the key advantages of the copper wire granulator is its ability to effectively separate copper from plastic after the crushing process. This separation process is essential for recycling applications, as it allows for the recovery of high-quality copper while minimizing waste and environmental impact. The resulting copper purity achieved through this process is an impressive 99.9%, making it a valuable resource for various manufacturing and production needs.

The high copper purity obtained through the granulation process makes the recovered copper highly desirable for reuse in the production of new materials, components, and products. This not only contributes to sustainable resource management but also reduces the reliance on virgin copper mining, thereby promoting environmental conservation and responsible resource utilization.

Furthermore, the efficient separation of copper from plastic also contributes to the overall economic viability of recycling operations. By maximizing the recovery of valuable copper and minimizing waste, the copper wire granulator helps to optimize the economic benefits of recycling while reducing the environmental footprint associated with traditional disposal methods.

In conclusion, the copper wire granulator is an indispensable tool for the recycling and processing of copper wires. Its ability to crush and separate various types of copper wires, coupled with its impressive copper purity of 99.9%, makes it a valuable asset for industries involved in sustainable resource management, environmental conservation, and responsible manufacturing practices. By facilitating the efficient recovery and reuse of copper, the copper wire granulator plays a vital role in promoting a circular economy and reducing the environmental impact of copper production and disposal.

Raw materials for processing

Raw materials for processing- 01All kinds of Copper cable and wire;

- 02Aluminum cable and wire;

- 03Auto wiring harnesses;

- 04Communication cables;

- 05Household electric wire;

- 06Computer wire;

- 07Other unclassified cables which cannot be processed by wire-stripping machine.

Features

Features

- - PLC control cabinet guaranteethe processing safety and protect the machine life

- - integrated structure, easy to install and debug, convenient to transport, stable performance.

- - Blade and screen use special wear resistance and high toughness alloy materialto reduce the production cost.

- - double roller,low speed to guarantee the feeding efficiency

- - No dust, no secondary pollution

- - Copper purity 99.9%

- - Pulse dust collector

Technical Parameters

Technical Parameters|

Model |

Power (Kw) |

Weight (Kg) |

Capacity (Kg/H) |

Dimension of main part (mm) |

|

TM50 |

8.69 |

1100 |

40-70 |

1500*1550*2000 |

|

TM100 |

11.49 |

1800 |

70-100 |

1600*1550*2000 |

|

TM300 |

15.99 |

2000 |

100-200 |

1680*1850*2100 |

|

TM400 |

19.79 |

3500 |

200-300 |

2300*2000*2500 |

|

TM600 |

58.44 |

8000 |

300-500 |

3100*2100*2500 |

|

TM800 |

98 |

10000 |

500-800 |

5500*2100*3500 |

|

TM1000 |

66.44 |

13500 |

800-1000 |

6000*2200*4000 |

Related News

-

Troubleshooting Common Eddy Separator Problems

In the realm of recycling and material separation, eddy current separator, eddy separator, and eddy current sorting machine play a vital role in efficiently separating non - ferrous metals from various waste streams.

Read More -

The Role of Metal Recycling Plants in Circular Economy

In the pursuit of sustainable development, the circular economy has emerged as a crucial concept.

Read More -

The Impact of Recycling Line Pickers on Waste Management Costs

In the intricate landscape of waste management, every component plays a crucial role in determining operational costs.

Read More