Brief introduction

Twin shaft separator can crush scrap iron materials and other similar materials with high hardness by using special alloy cutting tools. It has characteristics of large torque, high efficiency, and low noise. This series of crushers are especially suitable for materials containing metal or stones and packaged into bundles or large sizes for all kinds of scrap. By cutting in this way it can increase the accumulation density of materials, reduce the transportation cost or benefit for further processing, such as separation.

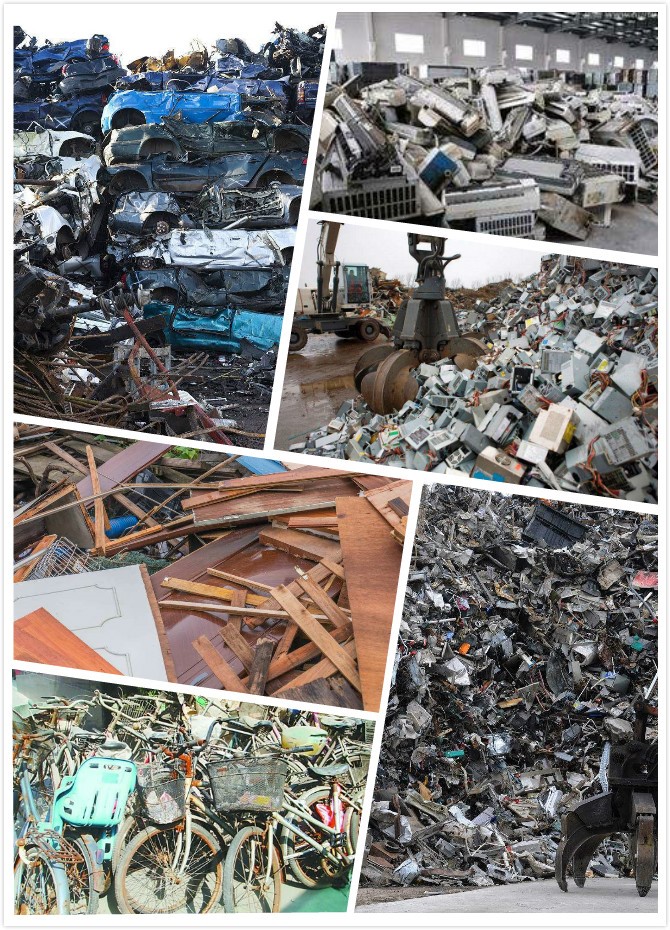

Raw materials for processing:

1. Metal : Cans, metal cans, iron plates, bicycles, car casings, etc

2. Wood : used furniture, branches and stems, wood trimmings, wooden pallets, solid wood, etc.

3.Rubber: Waste tires, tape, hose, industrial rubber products, etc.

4.Plastic: all kinds of plastic film, plastic bag, woven bag, plastic bottle, material frame, plastic block, plastic can, etc.

5.Pipe materials: plastic pipes, PE pipes, metal aluminum pipes, etc.

6.Domestic garbage: household garbage, kitchen garbage, industrial garbage, garden garbage, etc.

7.Electronics: refrigerator, circuit board, laptop case, TV case, etc

8.Paper : old books, newspapers, magazines, photocopier paper, etc.

9.Glass : lamp tube, glass cotton, glass, glass bottle and other glass products

10.Meat :animal or livestock, such as pork, bone, etc.

Features

1.Reasonable design, the body is made of welded steel.

2.Screw fastening, solid structure, durable.

3.Exquisite design, high productivity

4.Homogeneous material, lower consumption

5.Screen can be changed according to different demands

6.Cutting cools made of high hardness alloy processed by heat treatment.

7.The cutting tools has retractable and adjustable design, can be worn after blunt and repeated use

8.Equipped with larger pulley to increase the inertia of the crusher, energy saving and achieve powerful crushing

Technical Parameters

|

Model |

|

SP80 |

SP100 |

SP130 |

SP200 |

|

Capacity (t/h) |

Metal Materials |

1 |

1.5-2 |

2.2-2.5 |

2.5-3 |

|

Non-metal materials |

0.8 |

1 |

1.2 |

2 |

|

|

Rotor Diameter(mm) |

|

284 |

430 |

500 |

514 |

|

Rotation speed(rpm/m) |

|

15 |

15 |

15 |

10-30 |

|

Blade quantities (pcs) |

|

25 |

25 |

24 |

38 |

|

Width of blade(mm) |

|

20 |

40 |

50 |

50 |

|

Power (kw) |

|

15+15 |

22+22 |

30+30 |

45+45 |

|

Weight (kg) |

|

2400 |

3000 |

4000 |

7000 |

Related News

-

Eddy Separator for Non-Ferrous Metals

Onwang Technology Hebei Co.,Ltd. is at the forefront of developing cutting-edge eddy separator&

Read More -

E Waste Bin for Collected Spray Cans: Sustainable Disposal Solutions

Onwang Technology Hebei Co.,Ltd. specializes in advanced e-waste recycling solutions, offering high-

Read More -

Dual Shaft Shredder with Adjustable Blade Gaps

Onwang Technology Hebei Co.,Ltd. is a leading manufacturer specializing in industrial shredding solu

Read More