Granulators silig naxaas ah

Granulators silig naxaas ah

Hordhac kooban

Hordhac kooban

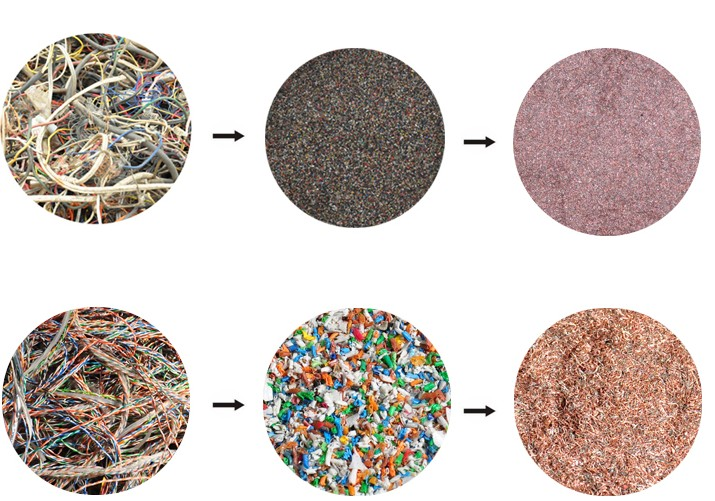

Mid ka mid ah faa'iidooyinka muhiimka ah ee granulator silig naxaas ah waa awoodda ay si wax ku ool ah uga soocdo naxaasta caagga ka dib habka jajabinta. Nidaamkan kala soocida ayaa muhiim u ah codsiyada dib-u-warshadaynta, maadaama ay u oggolaanayso soo kabashada naxaasta tayada sare leh iyada oo la yareynayo qashinka iyo saameynta deegaanka. Nadiifinta naxaasta ee ka dhalatay habkan ayaa ah mid cajiib ah 99.9%, taas oo ka dhigaysa kheyraad qiimo leh oo loogu talagalay baahiyaha wax soo saarka iyo wax soo saarka ee kala duwan.

Naxaasta sare ee nadiifka ah ee lagu helo habka granulation waxay ka dhigaysaa naxaasta la soo kabsaday mid aad loogu jecel yahay in dib loogu isticmaalo soo saarista alaabta cusub, qaybaha, iyo alaabta. Tani kaliya kama qayb qaadanayso maaraynta kheyraadka waara laakiin sidoo kale waxay yaraynaysaa ku tiirsanaanta macdanta naxaasta ee bikrada ah, iyada oo kor u qaadaysa ilaalinta deegaanka iyo ka faa'iidaysiga kheyraadka mas'uuliyadda leh.

Intaa waxaa dheer, kala-soocidda waxtarka leh ee naxaasta iyo balaastikada waxay sidoo kale gacan ka geysataa guud ahaan waxtarka dhaqaale ee hawlaha dib-u-warshadaynta. Iyadoo la kordhinayo soo kabashada naxaasta qiimaha leh iyo yaraynta qashinka, granulator silig naxaas ah ayaa ka caawiya in ay wanaajiso faa'iidooyinka dhaqaale ee dib-u-warshadaynta iyada oo la dhimayo raadka deegaanka ee la xidhiidha hababka qashinka dhaqameed.

Gebagebadii, granulator-ka siliga naxaasta ah waa qalab lagama maarmaan u ah dib-u-warshadaynta iyo habaynta fiilooyinka naxaasta. Awoodeeda lagu burburiyo oo kala saaro noocyada kala duwan ee fiilooyinka naxaasta ah, oo ay weheliso nadiifnimadeeda naxaasta ah ee 99.9%, ayaa ka dhigaysa hanti qiimo leh oo loogu talagalay warshadaha ku lug leh maaraynta kheyraadka waara, ilaalinta deegaanka, iyo dhaqamada wax soo saarka ee masuulka ka ah. Fududeynta dib-u-soo-kabashada hufan iyo dib-u-isticmaalka naxaasta, granulator-ka siligga naxaasta ah wuxuu door muhiim ah ka ciyaaraa horumarinta dhaqaalaha wareegtada iyo yaraynta saameynta deegaanka ee wax soo saarka iyo tuurista naxaasta.

Alaabta ceeriin ee farsamaynta

Alaabta ceeriin ee farsamaynta- 01Dhammaan noocyada fiilada Copper iyo silig;

- 02Fiilada aluminiumka iyo fiilada;

- 03Xadhkaha fiilooyinka baabuurta;

- 04Xadhkaha isgaadhsiinta;

- 05Siliga korontada ee guriga;

- 06Siliga kombiyuutarka;

- 07Fiilooyin kale oo aan la kala saarin oo aan lagu farsamayn karin mishiinka silig-goynta.

Astaamaha

Astaamaha

- - Golaha kontoroolka PLC waxay dammaanad qaadayaan badbaadada habaynta iyo ilaalinta nolosha mashiinka

- - qaab-dhismeed isku dhafan, fududahay in la rakibo oo laga saaro, ku habboon gaadiidka, waxqabadka xasilloon.

- - Daabka iyo shaashadu waxay isticmaalaan caabbinta xidhashada gaarka ah iyo walxaha daawaynta adag ee adag si loo yareeyo kharashka wax soo saarka.

- - roller double,xawaaraha hooseeya si loo dammaanad qaado waxtarka quudinta

- - Boodh ma jiro, wasakh labaadna ma jirto

- - Naxaas nadiif ah 99.9%

- - Boodh ururiyaha garaaca wadnaha

Qiyaasta Farsamada

Qiyaasta Farsamada|

Qaabka |

Awood (Kw) |

Miisaanka (Kg) |

Awoodda (Kg/H) |

Cabirka ee qaybta ugu weyn (mm) |

|

TM50 |

8.69 |

1100 |

40-70 |

1500*1550*2000 |

|

TM100 |

11.49 |

1800 |

70-100 |

1600*1550*2000 |

|

TM300 |

15.99 |

2000 |

100-200 |

1680*1850*2100 |

|

TM400 |

19.79 |

3500 |

200-300 |

2300*2000*2500 |

|

TM600 |

58.44 |

8000 |

300-500 |

3100*2100*2500 |

|

TM800 |

98 |

10000 |

500-800 |

5500*2100*3500 |

|

TM1000 |

66.44 |

13500 |

800-1000 |

6000*2200*4000 |

Wararka la xidhiidha

-

Troubleshooting Common Eddy Separator Problems

In the realm of recycling and material separation, eddy current separator, eddy separator, and eddy current sorting machine play a vital role in efficiently separating non - ferrous metals from various waste streams.

Akhri wax dheeraad ah -

The Role of Metal Recycling Plants in Circular Economy

In the pursuit of sustainable development, the circular economy has emerged as a crucial concept.

Akhri wax dheeraad ah -

The Impact of Recycling Line Pickers on Waste Management Costs

In the intricate landscape of waste management, every component plays a crucial role in determining operational costs.

Akhri wax dheeraad ah