Li-granulator tsa terata ea koporo

Li-granulator tsa terata ea koporo

Kenyelletso e khutšoanyane

Kenyelletso e khutšoanyane

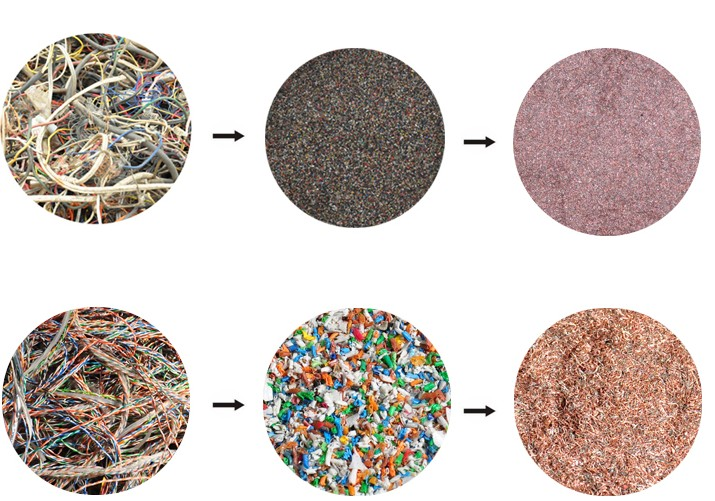

E 'ngoe ea melemo e ka sehloohong ea granulator ea terata ea koporo ke bokhoni ba eona ba ho arola koporo ka katleho ho tloha polasetiki ka mor'a ts'ebetso ea ho senya. Ts'ebetso ena ea karohano ke ea bohlokoa bakeng sa ho tsosolosa likopo, kaha e lumella ho hlaphoheloa ha koporo ea boleng bo phahameng ha e ntse e fokotsa litšila le tšusumetso ea tikoloho. Sephetho sa bohloeki ba koporo bo fihlelletsoeng ka ts'ebetso ena ke 99.9% e tsotehang, e etsang hore e be mohloli oa bohlokoa bakeng sa litlhoko tse fapaneng tsa tlhahiso le tlhahiso.

Bohloeki bo phahameng ba koporo bo fumanoang ka mokhoa oa granulation bo etsa hore koporo e fumanoeng e lakatsehe haholo bakeng sa ho sebelisoa hape ha ho etsoa thepa e ncha, likaroloana le lihlahisoa. Sena ha se kenye letsoho feela taolong ea moshoelella ea lisebelisuoa empa hape se fokotsa ts'epo ea merafo ea koporo e sa lebelloang, ka hona se khothaletsa paballo ea tikoloho le ts'ebeliso ea mehloli e nang le boikarabelo.

Ho feta moo, karohano e nepahetseng ea koporo ho tloha polasetiki le eona e kenya letsoho molemong oa moruo oa ts'ebetso ea ho e sebelisa hape. Ka ho eketsa ts'ebetso ea koporo ea bohlokoa le ho fokotsa litšila, granulator ea terata ea koporo e thusa ho ntlafatsa melemo ea moruo ea ho sebelisoa hape ha e ntse e fokotsa sebaka sa tikoloho se amanang le mekhoa ea khale ea ho lahla.

Qetellong, granulator ea terata ea koporo ke sesebelisoa sa bohlokoa bakeng sa ho nchafatsa le ho lokisa lithapo tsa koporo. Bokhoni ba eona ba ho pshatla le ho arola mefuta e fapaneng ea likhoele tsa koporo, hammoho le bohloeki ba eona bo tsotehang ba koporo ba 99.9%, bo e etsa letlotlo la bohlokoa bakeng sa liindasteri tse amehang taolong e tsitsitseng ea lisebelisoa, paballo ea tikoloho le mekhoa e ikarabellang ea tlhahiso. Ka ho thusa ho hlaphoheloa hantle le ho sebelisoa hape ha koporo, granulator ea terata ea koporo e bapala karolo ea bohlokoa ho holiseng moruo o chitja le ho fokotsa tšusumetso ea tikoloho ea tlhahiso le ho lahla koporo.

Lisebelisoa tse tala bakeng sa ho sebetsa

Lisebelisoa tse tala bakeng sa ho sebetsa- 01Mefuta eohle ea thapo ea Koporo le terata;

- 02Mohala oa aluminium le terata;

- 03Lithapo tsa lithapo tsa Auto;

- 04Lithapo tsa puisano;

- 05Mohala oa motlakase oa ntlo;

- 06Mohala oa khomphutha;

- 07Lithapo tse ling tse sa hlophisoang tse ke keng tsa sebetsoa ka mochini o khoahlatsang mohala.

Likaroloana

Likaroloana

- - Khabinete ea taolo ea PLC e netefatsa polokeho ea ts'ebetso le ho sireletsa bophelo ba mochini

- - sebopeho se kopaneng, se bonolo ho se kenya le ho se lokisa, se loketseng ho se tsamaisa, ts'ebetso e tsitsitseng.

- - Blade le skrine li sebelisa khanyetso e khethehileng ea ho roala le lisebelisoa tse phahameng tsa alloy ho fokotsa litšenyehelo tsa tlhahiso.

- - roller e habeli, lebelo le tlase ho netefatsa ts'ebetso ea phepo e nepahetseng

- - Ha ho lerōle, ha ho na tšilafalo ea bobeli

- - Bohloeki ba koporo 99.9%

- - Pokello ea lerōle la Pulse

Tekheniki Parameters

Tekheniki Parameters|

Mohlala |

Matla (Kw) |

Boima (Kg) |

Bokhoni (Kg/H) |

Boemo ea karolo e kholo (mm) |

|

TM50 |

8.69 |

1100 |

40-70 |

1500*1550*2000 |

|

TM100 |

11.49 |

1800 |

70-100 |

1600*1550*2000 |

|

TM300 |

15.99 |

2000 |

100-200 |

1680*1850*2100 |

|

TM400 |

19.79 |

3500 |

200-300 |

2300*2000*2500 |

|

TM600 |

58.44 |

8000 |

300-500 |

3100*2100*2500 |

|

TM800 |

98 |

10000 |

500-800 |

5500*2100*3500 |

|

TM1000 |

66.44 |

13500 |

800-1000 |

6000*2200*4000 |

Litaba Tse Amanang

-

Troubleshooting Common Eddy Separator Problems

In the realm of recycling and material separation, eddy current separator, eddy separator, and eddy current sorting machine play a vital role in efficiently separating non - ferrous metals from various waste streams.

Bala haholoanyane -

The Role of Metal Recycling Plants in Circular Economy

In the pursuit of sustainable development, the circular economy has emerged as a crucial concept.

Bala haholoanyane -

The Impact of Recycling Line Pickers on Waste Management Costs

In the intricate landscape of waste management, every component plays a crucial role in determining operational costs.

Bala haholoanyane