Ejò waya granulators

Ejò waya granulators

Ifihan kukuru

Ifihan kukuru

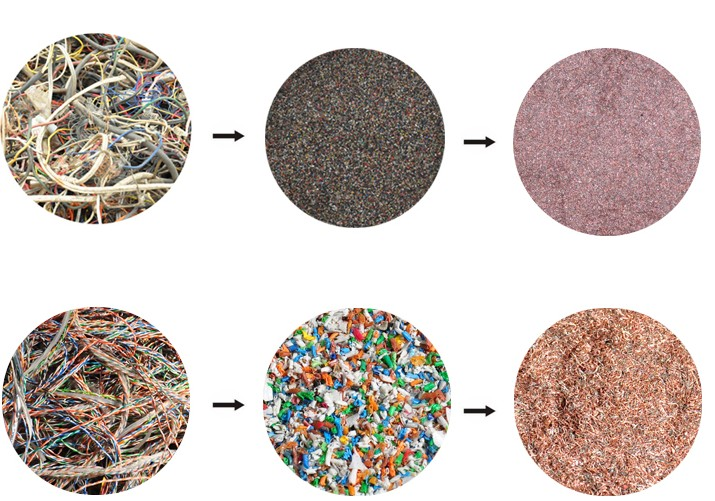

Ọkan ninu awọn anfani bọtini ti granulator waya Ejò ni agbara rẹ lati ṣe iyasọtọ bàbà daradara lati ṣiṣu lẹhin ilana fifun pa. Ilana iyapa yii jẹ pataki fun awọn ohun elo atunlo, bi o ṣe ngbanilaaye fun gbigbapada ti bàbà ti o ga julọ lakoko ti o dinku egbin ati ipa ayika. Iwa mimọ Ejò ti o waye nipasẹ ilana yii jẹ iwunilori 99.9%, ti o jẹ ki o jẹ orisun ti o niyelori fun ọpọlọpọ iṣelọpọ ati awọn iwulo iṣelọpọ.

Iwa mimọ bàbà giga ti o gba nipasẹ ilana granulation jẹ ki Ejò ti o gba pada jẹ iwunilori pupọ fun ilotunlo ni iṣelọpọ awọn ohun elo tuntun, awọn paati, ati awọn ọja. Eyi kii ṣe idasi nikan si iṣakoso awọn orisun alagbero ṣugbọn o tun dinku igbẹkẹle lori iwakusa bàbà wundia, nitorinaa igbega itọju ayika ati lilo awọn orisun lodidi.

Pẹlupẹlu, iyapa daradara ti bàbà lati pilasitik tun ṣe alabapin si ṣiṣeeṣe eto-aje gbogbogbo ti awọn iṣẹ atunlo. Nipa mimu-pada sipo ti bàbà ti o niyelori ati idinku egbin, granulator okun waya Ejò ṣe iranlọwọ lati mu awọn anfani eto-ọrọ aje ti atunlo lakoko ti o dinku ifẹsẹtẹ ayika ti o ni nkan ṣe pẹlu awọn ọna isọnu ibile.

Ni ipari, granulator waya Ejò jẹ ohun elo ti ko ṣe pataki fun atunlo ati sisẹ awọn onirin bàbà. Agbara rẹ lati fọ ati ya awọn oriṣiriṣi oriṣi ti awọn okun onirin bàbà, papọ pẹlu mimọ idẹ didan rẹ ti 99.9%, jẹ ki o jẹ dukia ti o niyelori fun awọn ile-iṣẹ ti o ni ipa ninu iṣakoso awọn orisun alagbero, itọju ayika, ati awọn iṣe iṣelọpọ lodidi. Nipa irọrun imularada daradara ati ilotunlo ti bàbà, granulator okun waya Ejò ṣe ipa pataki ninu igbega ọrọ-aje ipin kan ati idinku ipa ayika ti iṣelọpọ bàbà ati isọnu.

Awọn ohun elo aise fun sisẹ

Awọn ohun elo aise fun sisẹ- 01Gbogbo iru okun Ejò ati okun waya;

- 02Okun Aluminiomu ati okun waya;

- 03Awọn ohun ija onirin laifọwọyi;

- 04Awọn kebulu ibaraẹnisọrọ;

- 05Okun ina mọnamọna ile;

- 06Kọmputa waya;

- 07Awọn kebulu miiran ti a ko ni iyasọtọ eyiti ko le ṣe ni ilọsiwaju nipasẹ ẹrọ yiyọ okun waya.

Awọn ẹya ara ẹrọ

Awọn ẹya ara ẹrọ

- - minisita iṣakoso PLC ṣe iṣeduro aabo sisẹ ati daabobo igbesi aye ẹrọ

- - eto iṣọpọ, rọrun lati fi sori ẹrọ ati yokokoro, rọrun lati gbe, iṣẹ iduroṣinṣin.

- - Blade ati iboju lo resistance yiya pataki ati ohun elo alloy toughness giga lati dinku idiyele iṣelọpọ.

- - ilọpo meji, iyara kekere lati ṣe iṣeduro ṣiṣe ifunni

- - Ko si eruku, ko si idoti keji

- - Iwa mimọ Ejò 99.9%

- - Polusi eruku-odè

Imọ paramita

Imọ paramita|

Awoṣe |

Agbara (Kw) |

Ìwúwo (Kg) |

Agbara (Kg/H) |

Iwọn ti akọkọ apakan (mm) |

|

TM50 |

8.69 |

1100 |

40-70 |

1500*1550*2000 |

|

TM100 |

11.49 |

1800 |

70-100 |

1600*1550*2000 |

|

TM300 |

15.99 |

2000 |

100-200 |

1680*1850*2100 |

|

TM400 |

19.79 |

3500 |

200-300 |

2300*2000*2500 |

|

TM600 |

58.44 |

8000 |

300-500 |

3100*2100*2500 |

|

TM800 |

98 |

10000 |

500-800 |

5500*2100*3500 |

|

TM1000 |

66.44 |

13500 |

800-1000 |

6000*2200*4000 |

Awọn iroyin ti o jọmọ

-

Troubleshooting Common Eddy Separator Problems

In the realm of recycling and material separation, eddy current separator, eddy separator, and eddy current sorting machine play a vital role in efficiently separating non - ferrous metals from various waste streams.

Ka siwaju -

The Role of Metal Recycling Plants in Circular Economy

In the pursuit of sustainable development, the circular economy has emerged as a crucial concept.

Ka siwaju -

The Impact of Recycling Line Pickers on Waste Management Costs

In the intricate landscape of waste management, every component plays a crucial role in determining operational costs.

Ka siwaju