Metal Balers

Brief introduction

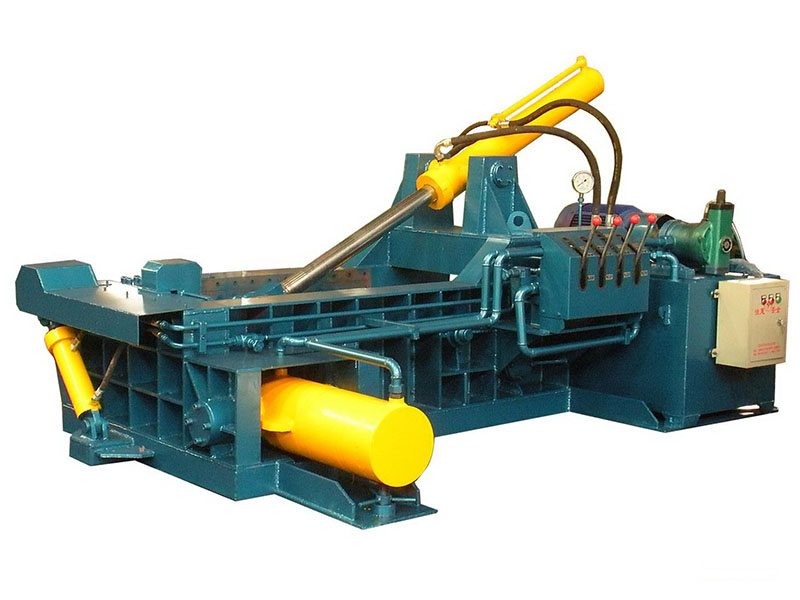

Hydraulic metal baler machine is applicable in steel plants, recycling companies, ferrous &non-ferrous smelting industry to press metal scraps, steel, copper, aluminum, stainless steel, discarded automobiles, into acceptable furnace charges, so as to reduce cost of transportation, to increase speed of furnace charging. non-metal hydraulic baling machine, which is widely used to compress and pack the relaxed goods such as cotton, yarn, cloth, hemp, wool and other products. The compressed package block has the uniform outer dimension and the large density and proportion, which is suitable for container transportation.

Raw materials for processing:

Horizontal hydraulic scrap metal balers are applicable in steel plants, recycling companies, ferrous& non-ferrous smelting industry to press metal scraps ( steel, copper, aluminum, stainless steel, discarded automobiles).

Features

1. Options for different force, press box size &bale size.

2. Use diesel engine when electrical motor is unavailable.

3. With safety warning labels and emergency button stop.

Technical Parameters

| Model | Nominal Force | Press Box Size (L*W*H) | Bale Size (W*H) | bale Density

(kg/m) |

Production Efficiency

(t/h) |

Single circle time(s) | Power (kw) |

|

DBM63 |

630 |

1000*600*500 |

200*200* 190 |

≥1800 |

0.9--1.1 |

80 |

7.5 |

|

BD80 |

800 |

1000*600*500 |

(180-250)*190*190 |

≥1800 |

2--4 |

90 |

11 |

|

BD100 |

1000 |

1000*600*500 |

(200-300)*200*200 |

≥1800 |

3--5 |

120 |

15 |

|

BD125 |

1250 |

1150*700*600 |

(150-400)*250*250 |

≥1800 |

4-6 |

120 |

15-18.5 |

|

DBM100 |

1000 |

1200*600*600 |

(250-400)*240*240 |

≥1800 |

2.5-4 |

120 |

15 |

|

DBM125 |

1250 |

1200*700*600 |

(250-400)*240*241 |

≥1800 |

3-4.5 |

80 |

18.5 |

|

1400*650*650 |

(250-400)*300*300 |

||||||

|

DBM135 |

1350 |

1050*600*600 |

300*600*240 |

≥1800 |

5-7 |

150 |

22 |

|

1400*650*650 |

|||||||

|

DBM150 |

1500 |

900*550*500 |

300*400*250 |

≥1800 |

7-8 |

120 |

22 |

|

DBM160 |

1600 |

1600*1000*800 |

(400-600)*350*350 |

≥1800 |

8-9 |

150 |

22 |

|

(400-600)*400*400 |

|||||||

|

DBM180 |

1800 |

1600*1000*800 |

600*350*350 |

≥1800 |

15-20 |

150 |

22 |

|

DBM200 |

2000 |

1600*1200*800 |

700*400*400 |

≥1800 |

20-30 |

160 |

30 |

|

DBM220 |

2000 |

1800*1200*800 |

1800*1200*800 |

≥1800 |

18-25 |

160 |

37 |

|

DBM250 |

2500 |

2000*200*1400*900 |

800*500*500 |

≥1800 |

30-40 |

160 |

37 |

|

DBM280 |

2800 |

2000*1750*1200 |

800*500*600 |

≥1800 |

35-45 |

160 |

44 |

|

DBM315 |

3150 |

2000*1500*1200 |

1000*500*600 |

≥1800 |

50-60 |

160 |

60 |

Related News

-

eddy-separator-for-non-ferrous-metals

Onwang Technology Hebei Co.,Ltd. is at the forefront of developing cutting-edge eddy separator&

Read More -

e-waste-bin-for-collected-spray-cans-sustainable-disposal-solutions

Onwang Technology Hebei Co.,Ltd. specializes in advanced e-waste recycling solutions, offering high-

Read More -

dual-shaft-shredder-with-adjustable-blade-gaps

Onwang Technology Hebei Co.,Ltd. is a leading manufacturer specializing in industrial shredding solu

Read More