Metal Ballers

Koarte yntroduksje

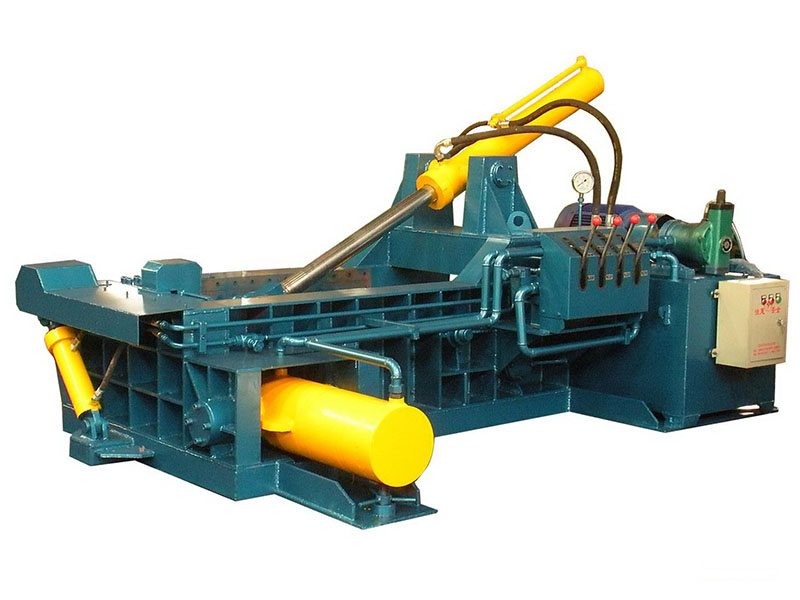

Hydraulyske metalen balermasjine is fan tapassing yn stielfabriken, recyclingbedriuwen, ferro- en non-ferro-smeltingsindustry om metalen skrappen, stiel, koper, aluminium, roestfrij stiel, ôfskaft auto's, yn akseptabele ovenkosten te drukken, om de kosten fan ferfier te ferminderjen, oant fergrutsje snelheid fan furnace opladen. net-metaal hydraulyske baling masine, dy't in soad brûkt wurdt om de ûntspannen guod lykas katoen, garen, doek, hennep, wol en oare produkten te komprimearjen en te pakken. De komprimearre pakket blok hat de unifoarm bûtenste diminsje en de grutte tichtens en oanpart, dat is geskikt foar container ferfier.

Grûnstoffen foar ferwurking:

Horizontale hydraulyske skrapmetaalbalers binne fan tapassing yn stielplanten, recyclingbedriuwen, ijzer- en non-ferro smelten yndustry om metalen skrapkes te drukken (stiel, koper, aluminium, roestfrij stiel, ôfskaft auto's).

Features

1. Opsjes foar ferskillende krêft, druk doaze grutte & bale grutte.

2. Brûk dieselmotor as elektryske motor is net beskikber.

3. Mei feiligens warskôging labels en need knop stop.

Technyske parameters

| Model | Nominale krêft | Drukkastgrutte (L*W*H) | Bale Size (W*H) | bale Tichtheid

(kg/m) |

Produksje Effisjinsje

(t/h) |

Ien sirkel tiid(en) | Krêft (kw) |

|

DBM63 |

630 |

1000*600*500 |

200*200* 190 |

≥1800 |

0.9--1.1 |

80 |

7.5 |

|

BD80 |

800 |

1000*600*500 |

(180-250)*190*190 |

≥1800 |

2--4 |

90 |

11 |

|

BD100 |

1000 |

1000*600*500 |

(200-300)*200*200 |

≥1800 |

3--5 |

120 |

15 |

|

BD125 |

1250 |

1150*700*600 |

(150-400)*250*250 |

≥1800 |

4-6 |

120 |

15-18.5 |

|

DBM100 |

1000 |

1200*600*600 |

(250-400)*240*240 |

≥1800 |

2.5-4 |

120 |

15 |

|

DBM125 |

1250 |

1200*700*600 |

(250-400)*240*241 |

≥1800 |

3-4.5 |

80 |

18.5 |

|

1400*650*650 |

(250-400)*300*300 |

||||||

|

DBM135 |

1350 |

1050*600*600 |

300*600*240 |

≥1800 |

5-7 |

150 |

22 |

|

1400*650*650 |

|||||||

|

DBM150 |

1500 |

900*550*500 |

300*400*250 |

≥1800 |

7-8 |

120 |

22 |

|

DBM160 |

1600 |

1600*1000*800 |

(400-600)*350*350 |

≥1800 |

8-9 |

150 |

22 |

|

(400-600)*400*400 |

|||||||

|

DBM180 |

1800 |

1600*1000*800 |

600*350*350 |

≥1800 |

15-20 |

150 |

22 |

|

DBM200 |

2000 |

1600*1200*800 |

700*400*400 |

≥1800 |

20-30 |

160 |

30 |

|

DBM220 |

2000 |

1800*1200*800 |

1800*1200*800 |

≥1800 |

18-25 |

160 |

37 |

|

DBM250 |

2500 |

2000*200*1400*900 |

800*500*500 |

≥1800 |

30-40 |

160 |

37 |

|

DBM280 |

2800 |

2000*1750*1200 |

800*500*600 |

≥1800 |

35-45 |

160 |

44 |

|

DBM315 |

3150 |

2000*1500*1200 |

1000*500*600 |

≥1800 |

50-60 |

160 |

60 |

Related News

-

Troubleshooting Common Eddy Separator Problems

In the realm of recycling and material separation, eddy current separator, eddy separator, and eddy current sorting machine play a vital role in efficiently separating non - ferrous metals from various waste streams.

Lês mear -

The Role of Metal Recycling Plants in Circular Economy

In the pursuit of sustainable development, the circular economy has emerged as a crucial concept.

Lês mear -

The Impact of Recycling Line Pickers on Waste Management Costs

In the intricate landscape of waste management, every component plays a crucial role in determining operational costs.

Lês mear