Brief introduction

Brief introduction

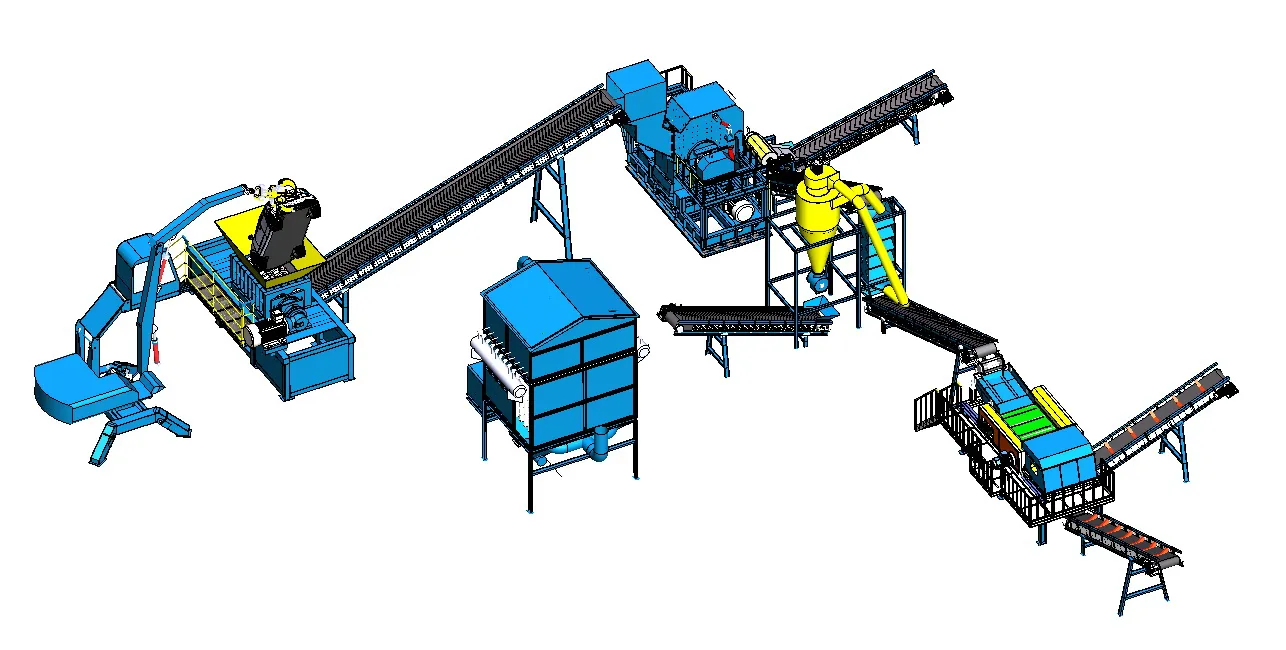

The scrap metal recycling line is composed of a heavy-duty double shaft shredder, a heavy-duty hammer crusher, conveying equipment, air separator, eddy current separator and a dust removal system. This line is mainly used for crushing and recycling metal scraps, automotive casings, aluminum castings, waste household appliances, and other materials. The double shaft shredder performs as pre crushing treatment on materials, while the hammer mill shredder performs as secondary crushing and cleans the surface of paint and dirt. Then the air separator can move some light things away from the line, such as light plastics, foams, etc. Here eddy current separator will separate ferrous metals from non ferrous metals . After processing, the material stacking density is suitable for direct transportation and return to the furnace. Compared with traditional high-speed horizontal hammer crushing equipment, the waste metal ash collection and crushing production line has significant advantages in equipment investment and maintenance costs

On the recycling line there is a magnetic separator. It will move the iron or steel away. Some materials need to add rotary screen to sort out the soil and classify the diffident size. Then the left materials will be in a high separation rate by eddy current separator.

The consist of the recycling line depends on your different demands of different raw materials. We can equip the recycling line according to your demands.

Recycling line capacity: 1-3 t/h, 3-5t/h, 5-10t/h, 10-15r/h, 15-20t/h, 20-30t/h . bigger capacity is also available.

Except metal recycling line we still have solid waste sorting line, electrical waste refrigerator recycling line, waste aluminum conduct wire recycling line, mixed copper wire and aluminum wire recycling plant etc.

As manufacturer, we can customize different recycling line according to your different raw materials with different demands and purpose. Welcome to contact us for details!

Related News

-

Eddy Separator for Non-Ferrous Metals

Onwang Technology Hebei Co.,Ltd. is at the forefront of developing cutting-edge eddy separator&

Read More -

E Waste Bin for Collected Spray Cans: Sustainable Disposal Solutions

Onwang Technology Hebei Co.,Ltd. specializes in advanced e-waste recycling solutions, offering high-

Read More -

Dual Shaft Shredder with Adjustable Blade Gaps

Onwang Technology Hebei Co.,Ltd. is a leading manufacturer specializing in industrial shredding solu

Read More