Eddy Current Separator

Eddy Current Separator

Brief introduction

Brief introduction- 01

Electronic waste disposal (refrigerator dismantling line).

- 02

Separation of aluminum cans and ferrous metals.

- 03

Separate aluminum or copper block from the sections of abandoned cars.

- 04

Separate non-ferrous metals from the glass scrap.

- 05

Separate non-ferrous metal impurities in some production lines(such as plastic recycling production line).

- 06

Separate non-ferrous metals from the wood.

Features

Features1.Easy to operate and install

2.Low energy consumption

3.Separate ferrous and non-ferrous metal automatically

4.Good sorting effect , and material with small size can be sorted.

5.Concentric rotor has large separation area and strong separation force.

6.A variety of models, a variety of structures for customers to choose

7.Protective device to give warning when it is in a dangerous condition

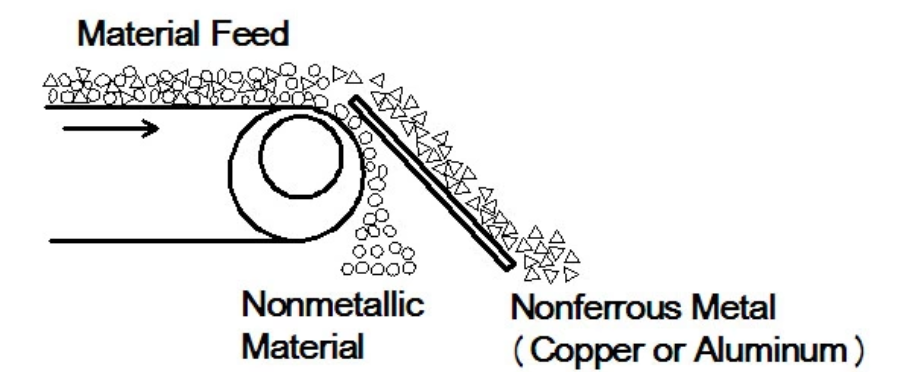

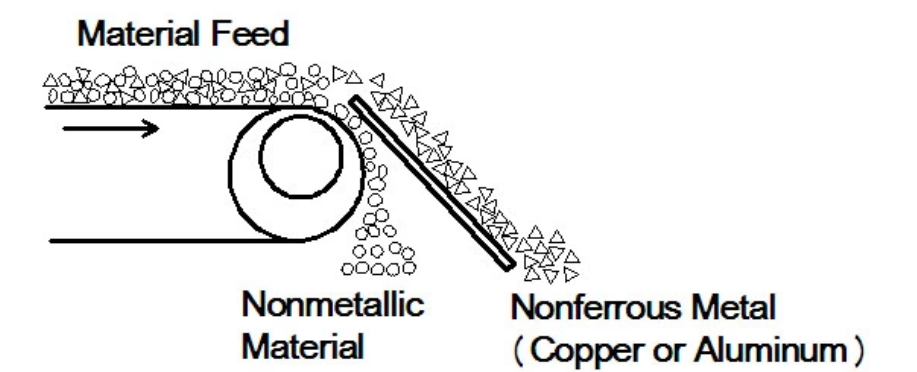

Working Principles

Working Principles

Eddy current separation is based on the use of a magnetic rotor with alternating polarity, spinning rapidly inside a non-metallic drum driven by a conveyor belt. As non-ferrous metals pass over the drum, the alternating magnetic field creates eddy currents in the non-ferrous metal particles repelling the material away from the conveyor. While other materials drop off at the end of the conveyor, the non-ferrous metals are propelled forward over a splitter for separation.

Technical Parameters

Technical Parameters|

Model |

Width of Belt (mm) |

Power (kw) |

Capacity (m3/h) |

Over all size L*W*H(mm) |

Weight (kg) |

|

ECS 600 |

600 |

10.5 |

3-5 |

3300*1500*1200 |

1000 |

|

ECS1000 |

1000 |

13.7 |

5-8 |

3300*1900*1500 |

1500 |

|

ECS1200 |

1200 |

19.95 |

8-10 |

3300*2100*1700 |

2000 |

|

ECS2000 |

2000 |

20.49 |

10-15 |

5100*2650*2000 |

2500 |

Related News

-

Troubleshooting Common Eddy Separator Problems

In the realm of recycling and material separation, eddy current separator, eddy separator, and eddy current sorting machine play a vital role in efficiently separating non - ferrous metals from various waste streams.

Read More -

The Role of Metal Recycling Plants in Circular Economy

In the pursuit of sustainable development, the circular economy has emerged as a crucial concept.

Read More -

The Impact of Recycling Line Pickers on Waste Management Costs

In the intricate landscape of waste management, every component plays a crucial role in determining operational costs.

Read More