Kev taw qhia luv luv

Twin ncej separator tuaj yeem tsoo cov khoom siv hlau thiab lwm yam ntaub ntawv zoo sib xws nrog cov hardness siab los ntawm kev siv cov cuab yeej tshwj xeeb alloy txiav. Nws muaj cov yam ntxwv ntawm lub zog loj, kev ua haujlwm siab, thiab tsis tshua muaj suab nrov. No series ntawm crushers yog tshwj xeeb tshaj yog haum rau cov ntaub ntawv uas muaj hlau los yog pob zeb thiab ntim rau hauv bundles los yog loj loj rau txhua yam ntawm seem. Los ntawm kev txiav nyob rau hauv txoj kev no nws tuaj yeem ua rau kom cov khoom ntim ntau ntxiv, txo cov nqi tsheb thauj mus los lossis tau txais txiaj ntsig rau kev ua haujlwm ntxiv, xws li kev sib cais.

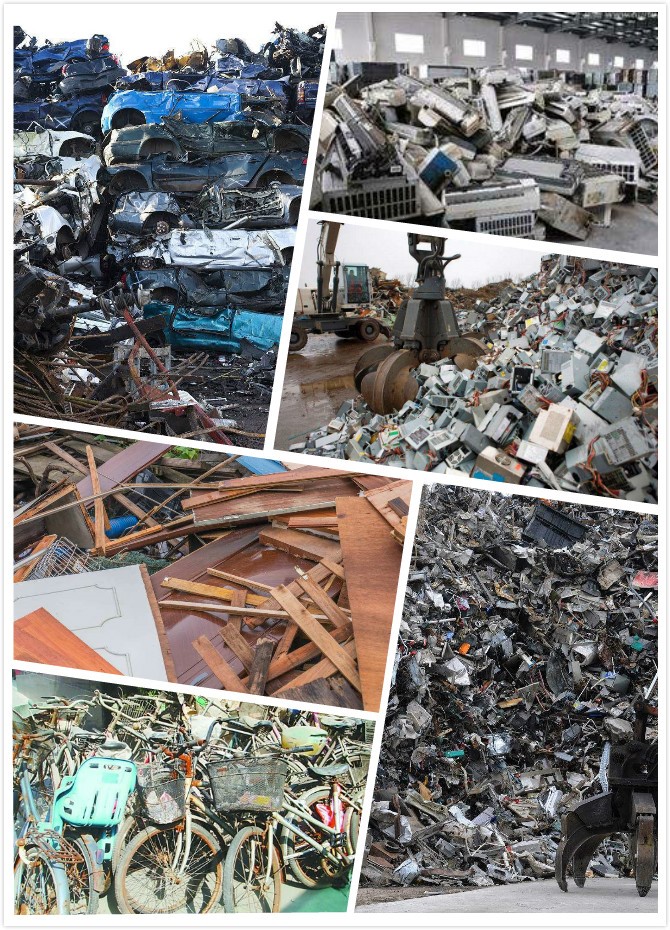

Raw khoom rau kev ua:

1. Hlau: cov kaus poom, cov kaus poom hlau, hlau phaj, tsheb kauj vab, tsheb casings, thiab lwm yam

2. Ntoo: siv rooj tog, ceg thiab stems, ntoo trimmings, ntoo pallets, khoom ntoo, thiab lwm yam.

3. Roj Hmab: Cov log tsheb khib nyiab, daim kab xev, hose, cov khoom siv roj hmab, thiab lwm yam.

4.Plastic: txhua yam yas zaj duab xis, hnab yas, woven hnab, lub raj mis yas, khoom thav duab, yas thaiv, yas tau, thiab lwm yam.

5.Pipe cov ntaub ntawv: cov kav dej yas, PE kav, hlau aluminium kav, thiab lwm yam.

6.Cov khib nyiab hauv tsev: cov khib nyiab hauv tsev, cov khib nyiab hauv tsev, cov khib nyiab khib nyiab, vaj khib nyiab, thiab lwm yam.

7.Electronics: tub yees, circuit board, laptop case, TV case, etc

8.Paper: cov phau ntawv qub, ntawv xov xwm, ntawv xov xwm, ntawv luam ntawv, thiab lwm yam.

9.Glass: lub teeb raj, iav paj rwb, iav, iav fwj thiab lwm yam khoom iav

10.Nqaij: tsiaj los yog tsiaj txhu, xws li nqaij npuas, pob txha, thiab lwm yam.

Nta

1. Tsim nyog tsim, lub cev yog ua los ntawm welded steel.

2.Screw fastening, khoom qauv, ruaj.

3.Exquisite tsim, siab productivity

4.Homogeneous khoom, tsawg noj

5.Screen tuaj yeem hloov pauv raws li qhov xav tau sib txawv

6.Cutting txias ua los ntawm siab hardness alloy ua los ntawm kev kho cua sov.

7.Cov cuab yeej txiav tau thim rov qab thiab kho tau tus qauv, tuaj yeem hnav tom qab blunt thiab rov siv dua

8.Equipped nrog loj pulley kom lub inertia ntawm lub crusher, lub zog txuag thiab ua kom muaj zog crushing

Technical Parameters

|

Qauv |

|

SIB 80 |

PIB 100 |

SIB 130 |

SIB 200 |

|

Peev xwm (t / h) |

Cov khoom siv hlau |

1 |

1.5-2 |

2.2-2.5 |

2.5-3 |

|

Cov khoom siv tsis yog hlau |

0.8 |

1 |

1.2 |

2 |

|

|

Rotor txoj kab uas hla (mm) |

|

284 |

430 |

500 |

514 |

|

Kev sib hloov ceev (rpm / m) |

|

15 |

15 |

15 |

10-30 |

|

Hniav kom muaj nuj nqis (pcs) |

|

25 |

25 |

24 |

38 |

|

Dav ntawm cov hniav (mm) |

|

20 |

40 |

50 |

50 |

|

Lub zog (kw) |

|

15+15 |

22+22 |

30+30 |

45+45 |

|

Qhov hnyav (kg) |

|

2400 |

3000 |

4000 |

7000 |

Cov xov xwm ntsig txog

-

Troubleshooting Common Eddy Separator Problems

In the realm of recycling and material separation, eddy current separator, eddy separator, and eddy current sorting machine play a vital role in efficiently separating non - ferrous metals from various waste streams.

Nyeem ntxiv -

The Role of Metal Recycling Plants in Circular Economy

In the pursuit of sustainable development, the circular economy has emerged as a crucial concept.

Nyeem ntxiv -

The Impact of Recycling Line Pickers on Waste Management Costs

In the intricate landscape of waste management, every component plays a crucial role in determining operational costs.

Nyeem ntxiv