Sep . 04, 2025 16:20 Back to list

In today’s world, where sustainability and resource conservation are top priorities, the role of metal recycling plants has become increasingly vital. A well-designed metal recycling facility not only reduces environmental impact but also recovers valuable raw materials for reuse, fueling the circular economy. Choosing the right metal recycling plant manufacturer is essential for ensuring reliable performance, efficient operation, and long-term return on investment. Alongside understanding the metal recycling plant cost, it is equally important to grasp how metals are sorted in recycling plants to optimize recovery and purity. This article explores these critical aspects to help businesses make informed decisions in metal recycling projects.

When embarking on a metal recycling project, partnering with an experienced metal recycling plant manufacturer is foundational to success. Such manufacturers offer comprehensive solutions, from initial design and engineering to installation and after-sales support. Their expertise ensures the plant can efficiently handle various metal types, including ferrous and non-ferrous materials, while complying with environmental and safety regulations.

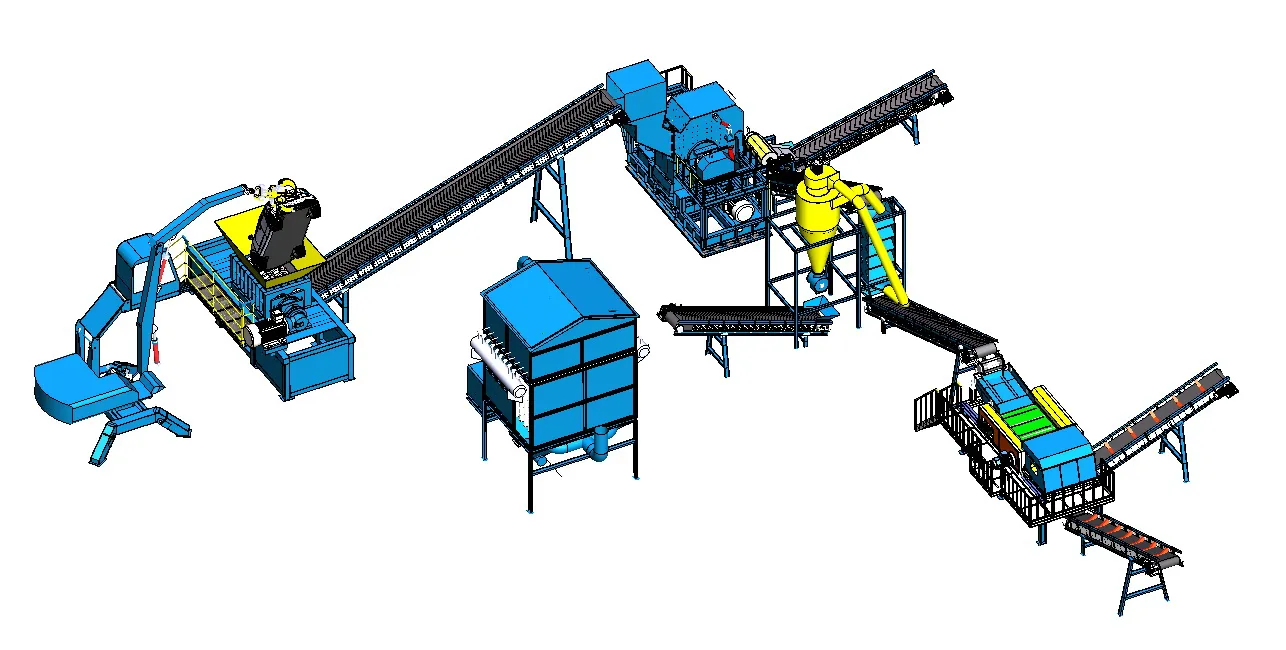

Reputable manufacturers also customize equipment layouts to fit available space and desired processing capacities. They integrate advanced sorting technologies like magnetic separators, eddy current separators, and optical sensors, tailored to meet specific operational goals. Furthermore, these manufacturers provide training for plant operators and maintenance teams, ensuring smooth plant commissioning and long-term reliability.

Determining the metal recycling plant cost involves considering several factors that affect both upfront investment and ongoing operational expenses. Plant capacity is a primary driver; larger facilities with higher throughput naturally require more extensive equipment and infrastructure. The types of metals processed—whether primarily steel, aluminum, copper, or mixed scrap—also influence equipment selection and complexity.

Additional cost considerations include automation level, with more automated plants generally demanding higher initial investment but offering reduced labor costs and increased precision. Location plays a role too, as shipping, installation, and regulatory compliance costs vary regionally. Finally, maintenance expenses, energy consumption, and spare parts availability contribute to the total cost of ownership. Evaluating these factors holistically ensures the selected plant delivers maximum value over its operational lifespan.

A key question in metal recycling operations is how are metals sorted in recycling plants to achieve high purity and efficiency. The process begins with material pre-sorting, often manually removing large contaminants. Ferrous metals, such as iron and steel, are then separated using magnetic separators, which attract magnetic metals away from the waste stream.

Non-ferrous metals like aluminum and copper are isolated by eddy current separators, which use rapidly changing magnetic fields to repel conductive metals. Advanced facilities incorporate sensor-based sorting technologies including optical sorters and X-ray transmission (XRT) systems to distinguish between different metal alloys and remove impurities. This layered sorting approach ensures high recovery rates and clean material streams ready for resale or further processing.

As global industries and governments push for carbon reduction and resource efficiency, metal recycling plants play a pivotal role in sustainable development. They help reduce reliance on virgin ore mining, lowering environmental degradation and energy use. The rising demand for recycled metals across automotive, construction, and electronics sectors further underscores the strategic value of investing in efficient recycling infrastructure.

Modern metal recycling plant manufacturers are innovating with modular designs and smart control systems that improve throughput and reduce downtime. These advancements enable plants to adapt to evolving material streams and regulatory requirements. By contributing to a circular economy, metal recycling facilities support environmental goals while providing economic benefits through material recovery and job creation.

A metal recycling plant manufacturer offers end-to-end solutions including plant design, engineering, equipment manufacturing, installation, and commissioning. They also provide after-sales support such as training, maintenance services, and parts supply to ensure continuous plant operation. Customization based on the client’s specific metal processing needs and compliance with local regulations is typically part of their service package.

The metal recycling plant cost is influenced by plant capacity, types of metals processed, automation level, equipment sophistication, and geographical location. Larger plants with advanced sorting technologies and high automation will incur higher upfront costs but often deliver better long-term value through efficiency gains and reduced labor needs. Operational expenses like energy, maintenance, and spare parts also affect overall costs.

Ferrous metals such as iron and steel are separated primarily using magnetic separators. These devices generate magnetic fields that attract and remove magnetic metals from mixed waste streams. Magnetic separators can be configured as drum magnets, magnetic pulleys, or overband magnets depending on the plant layout and material flow, ensuring effective ferrous metal recovery.

Eddy current separators utilize rapidly changing magnetic fields produced by a high-speed rotor inside a non-magnetic drum. These fields induce eddy currents in conductive non-ferrous metals like aluminum and copper, creating repulsive forces that eject these metals from the waste stream. This technology enables high-speed, non-contact separation of valuable non-ferrous materials.

Efficient metal sorting is critical to maximize material recovery rates, reduce contamination, and improve the quality of recycled metals. High purity output increases resale value and reduces processing costs downstream. Effective sorting also minimizes landfill waste and environmental impact, supporting regulatory compliance and sustainability goals.

Latest news

Double Shaft Shredder Price Explained: Global Trends, Benefits & Vendor Comparisons

NewsNov.24,2025

Expert Insights into Double Shaft Shredder Factory: Boosting Global Recycling Efficiency

NewsNov.23,2025

Leading Double Shaft Shredder Suppliers for Industrial Recycling and Waste Management

NewsNov.23,2025

Leading Double Shaft Shredder Manufacturers | Durable & Sustainable Industrial Shredders

NewsNov.23,2025

Understanding Double Shaft Shredder Machine Price: Buyers’ Guide & Global Insights

NewsNov.22,2025

The Essential Guide to Double Shaft Shredders: Benefits, Applications & Trends

NewsNov.22,2025