Jun . 27, 2024 01:57 Back to list

By doing so, the need for raw materials from mining operations is reduced, conserving natural resources and lowering the environmental impact associated with steel production By doing so, the need for raw materials from mining operations is reduced, conserving natural resources and lowering the environmental impact associated with steel production

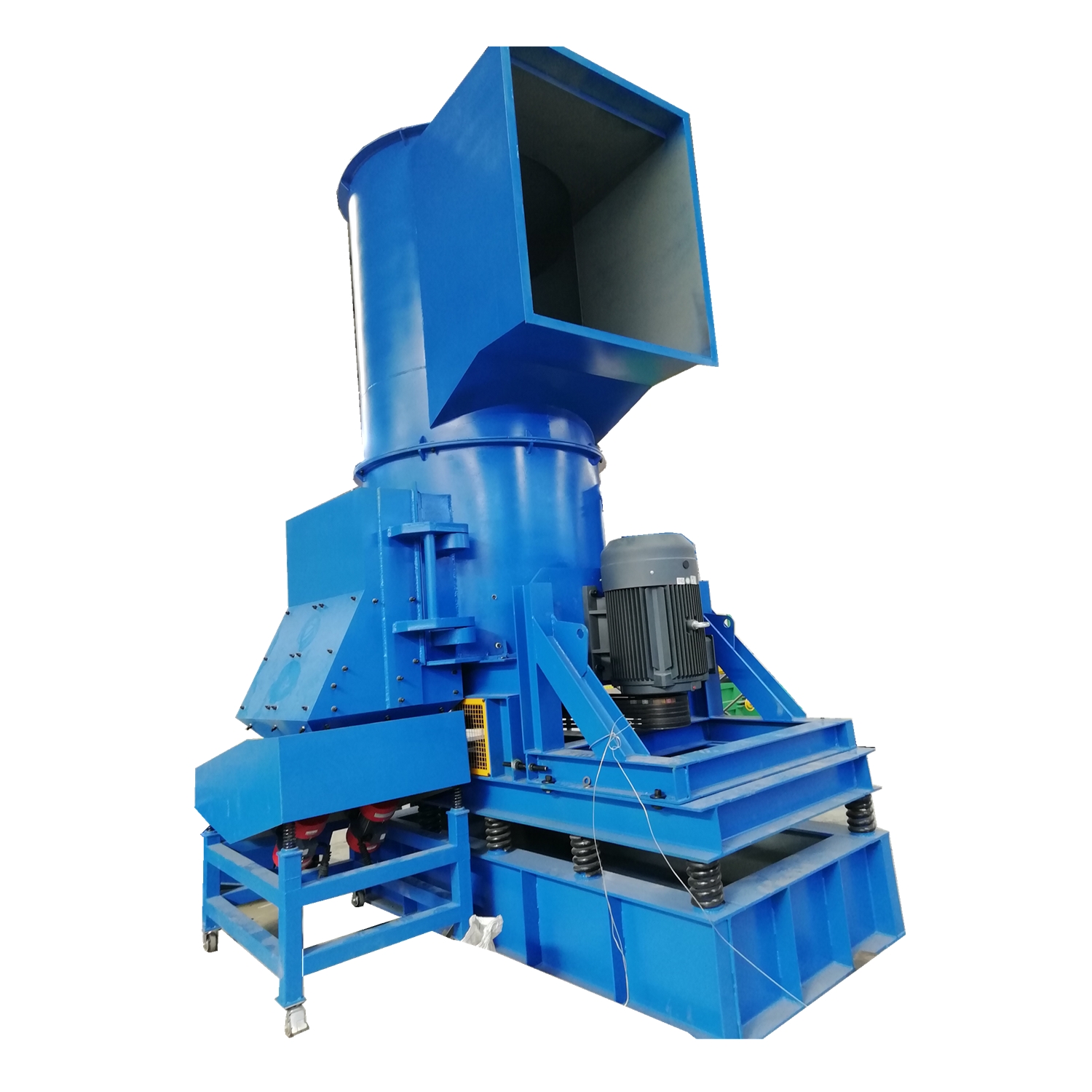

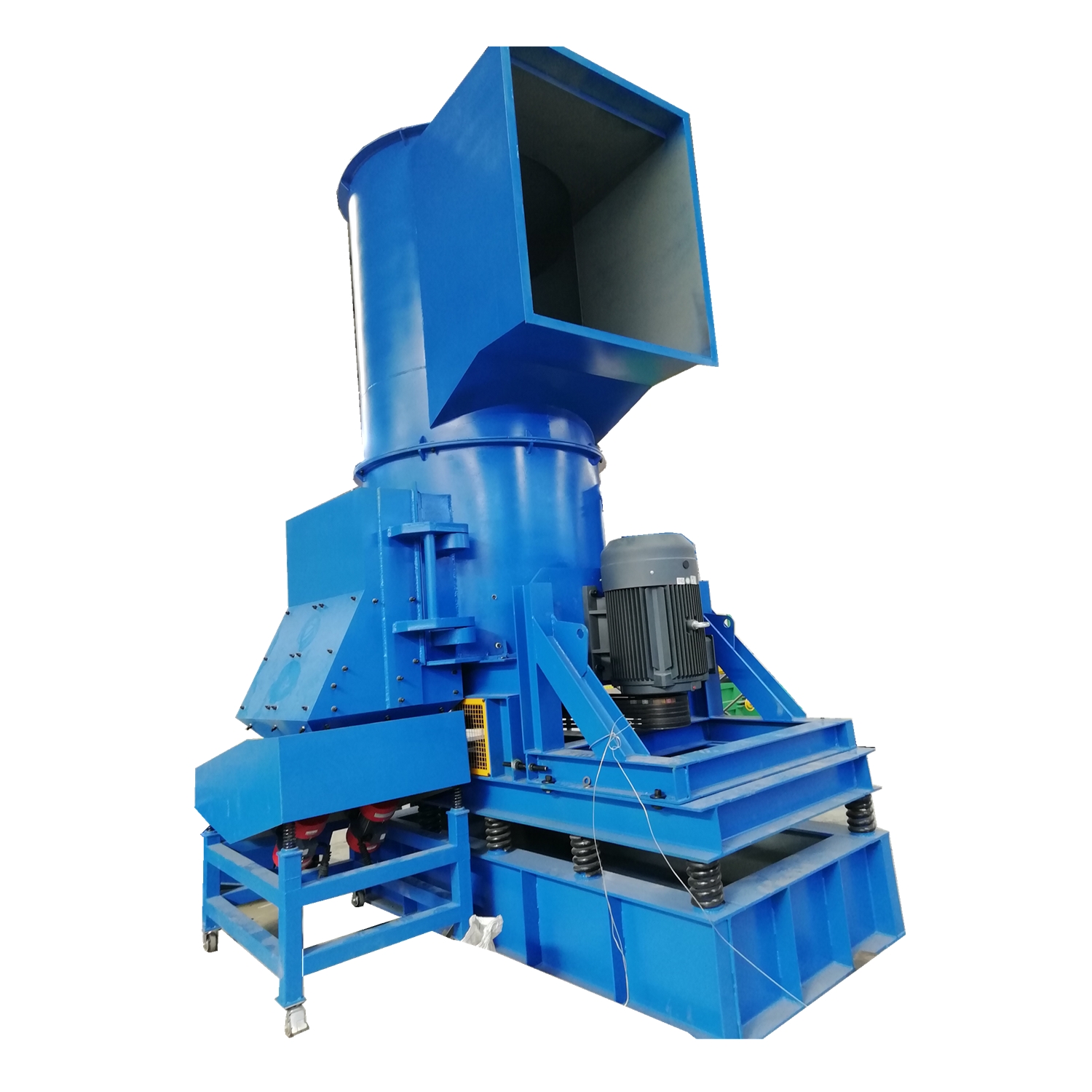

By doing so, the need for raw materials from mining operations is reduced, conserving natural resources and lowering the environmental impact associated with steel production By doing so, the need for raw materials from mining operations is reduced, conserving natural resources and lowering the environmental impact associated with steel production steel scrap shredder machine.

In addition to its primary function in recycling, the steel scrap shredder machine also offers benefits in terms of safety and efficiency in waste management. By reducing the volume of the scrap, it requires less storage space and is safer to transport. Furthermore, the reduction in size greatly facilitates the separation of different types of metals, which can be individually sold for recycling.

Environmental concerns have made the steel scrap shredder machine increasingly popular as industries strive to become more sustainable. The ability to recover and reuse materials decreases the demand for new resource extraction while simultaneously reducing the amount of waste that ends up in landfills or pollutes the environment.

In summary, the steel scrap shredder machine is an essential tool for efficient metal recycling. It not only aids in the conservation of resources but also supports eco-friendly practices by minimizing waste and pollution. As technology continues to advance, these machines will likely become even more sophisticated, further enhancing their role in promoting a circular economy where materials are perpetually reused and recycled.

steel scrap shredder machine.

In addition to its primary function in recycling, the steel scrap shredder machine also offers benefits in terms of safety and efficiency in waste management. By reducing the volume of the scrap, it requires less storage space and is safer to transport. Furthermore, the reduction in size greatly facilitates the separation of different types of metals, which can be individually sold for recycling.

Environmental concerns have made the steel scrap shredder machine increasingly popular as industries strive to become more sustainable. The ability to recover and reuse materials decreases the demand for new resource extraction while simultaneously reducing the amount of waste that ends up in landfills or pollutes the environment.

In summary, the steel scrap shredder machine is an essential tool for efficient metal recycling. It not only aids in the conservation of resources but also supports eco-friendly practices by minimizing waste and pollution. As technology continues to advance, these machines will likely become even more sophisticated, further enhancing their role in promoting a circular economy where materials are perpetually reused and recycled. Latest news

Metal Recycling Plant Manufacturer | Efficient Scrap & Aluminum Recycling

NewsSep.01,2025

Metal Recycling Plant Manufacturer | Efficient & Custom Solutions

NewsAug.31,2025

Efficient Eddy Current Separator - Non-Ferrous Metal Recovery

NewsAug.30,2025

Industrial Double Shaft Shredder Machine: Powerful & Efficient Shredding

NewsAug.29,2025

High-Efficiency Copper Wire Granulators | Best Price for Sale

NewsAug.28,2025

Eddy Separator for Non-Ferrous Metals

NewsAug.22,2025