Jun . 26, 2024 14:40 Back to list

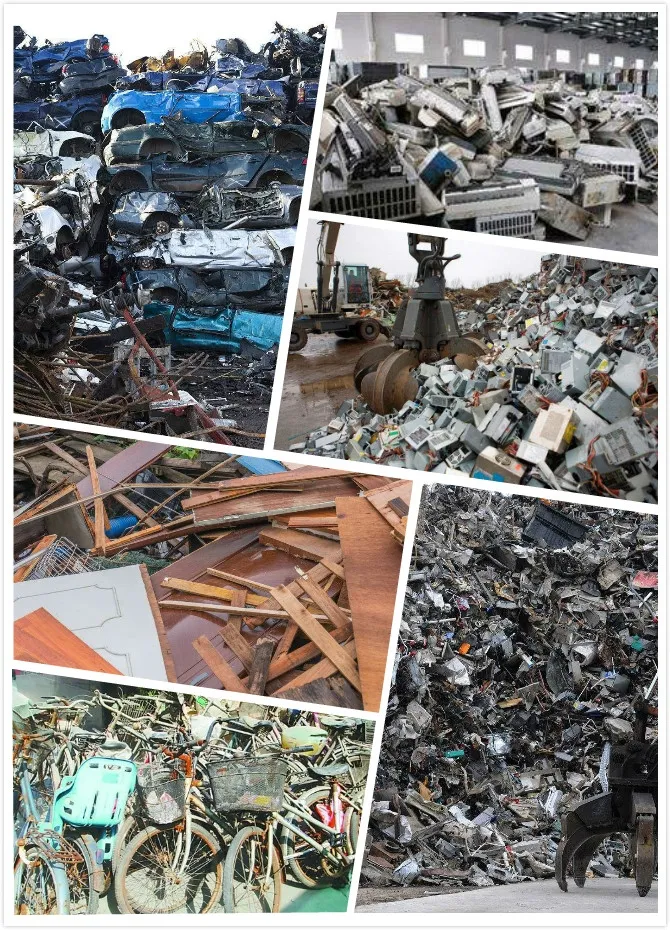

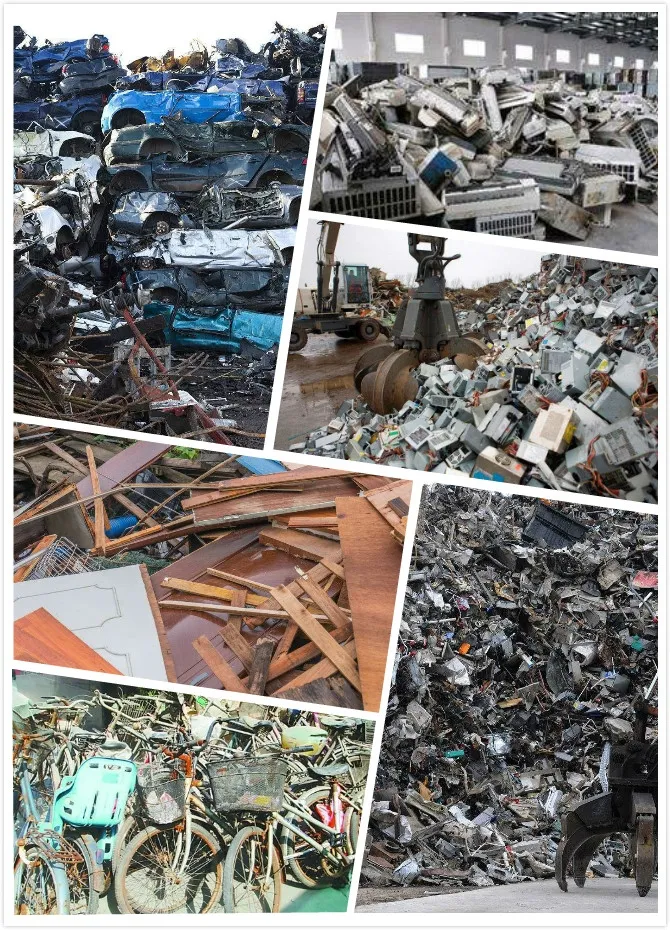

This process not only aids in resource recovery but also reduces landfill waste, contributing positively to environmental sustainability efforts This process not only aids in resource recovery but also reduces landfill waste, contributing positively to environmental sustainability efforts

This process not only aids in resource recovery but also reduces landfill waste, contributing positively to environmental sustainability efforts This process not only aids in resource recovery but also reduces landfill waste, contributing positively to environmental sustainability efforts stainless steel shredder.

Food processing plants utilize stainless steel shredders to prepare ingredients on a large scale. From cheese grating to vegetable chopping, these machines offer consistency and speed, outperforming manual labor and ensuring uniform product quality. The ease of cleaning and sanitation due to the stainless steel build only adds to their appeal in this sector.

Despite their robust nature, stainless steel shredders require careful operation and maintenance to maximize efficiency and longevity. Regular checks on the blades and bearings, along with prompt lubrication, prevent premature wear and potential breakdowns. However, the inherent properties of stainless steel greatly reduce the need for frequent repairs or component replacements compared to other materials.

In conclusion, stainless steel shredders are marvels of engineering that provide immense value across various sectors. Their ability to handle a plethora of materials, coupled with the enduring qualities of stainless steel, makes them an indispensable asset for any operation requiring size reduction. As technology continues to advance, one can only expect these machines to become even more sophisticated, enhancing their capabilities and expanding their applications.

stainless steel shredder.

Food processing plants utilize stainless steel shredders to prepare ingredients on a large scale. From cheese grating to vegetable chopping, these machines offer consistency and speed, outperforming manual labor and ensuring uniform product quality. The ease of cleaning and sanitation due to the stainless steel build only adds to their appeal in this sector.

Despite their robust nature, stainless steel shredders require careful operation and maintenance to maximize efficiency and longevity. Regular checks on the blades and bearings, along with prompt lubrication, prevent premature wear and potential breakdowns. However, the inherent properties of stainless steel greatly reduce the need for frequent repairs or component replacements compared to other materials.

In conclusion, stainless steel shredders are marvels of engineering that provide immense value across various sectors. Their ability to handle a plethora of materials, coupled with the enduring qualities of stainless steel, makes them an indispensable asset for any operation requiring size reduction. As technology continues to advance, one can only expect these machines to become even more sophisticated, enhancing their capabilities and expanding their applications. Latest news

Troubleshooting Common Eddy Separator Problems

NewsJul.04,2025

The Role of Metal Recycling Plants in Circular Economy

NewsJul.04,2025

The Impact of Recycling Line Pickers on Waste Management Costs

NewsJul.04,2025

Safety Features Every Metal Shredder Should Have

NewsJul.04,2025

How Industrial Shredders Improve Waste Management Systems

NewsJul.04,2025

How Cable Granulators Contribute to Sustainable Recycling

NewsJul.04,2025