Jun . 21, 2024 11:16 Back to list

Moreover, the use of small industrial metal shredders promotes economic benefits by creating value from what would otherwise be discarded materials

Moreover, the use of small industrial metal shredders promotes economic benefits by creating value from what would otherwise be discarded materials

Moreover, the use of small industrial metal shredders promotes economic benefits by creating value from what would otherwise be discarded materials

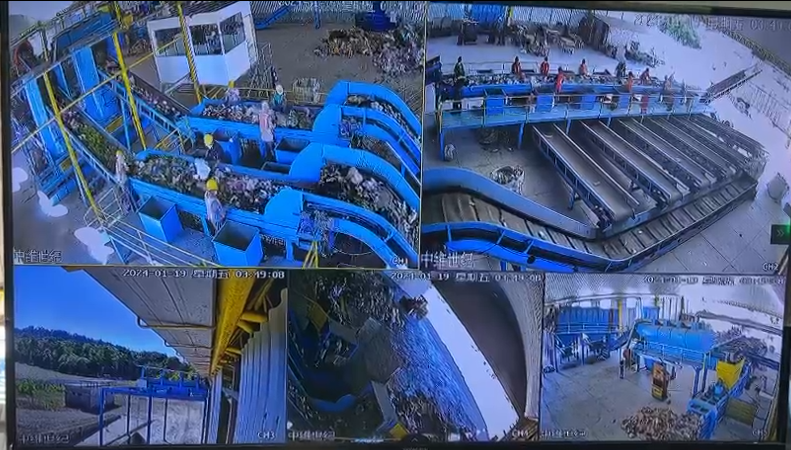

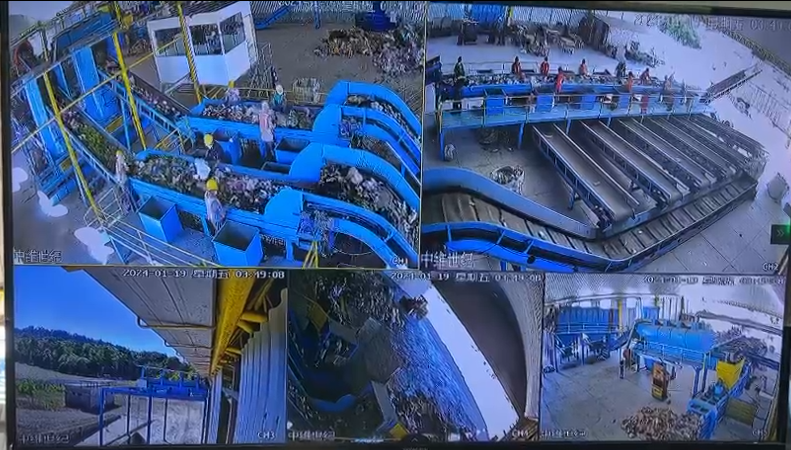

Moreover, the use of small industrial metal shredders promotes economic benefits by creating value from what would otherwise be discarded materials small industrial metal shredder. The recycled metal can be sold to foundries and manufacturing plants, generating income for recycling companies and fostering a circular economy. This approach not only conserves natural resources but also stimulates local economies by creating jobs within the recycling sector.

However, it is essential to consider the noise and dust emissions produced during the shredding process. Manufacturers continually strive to improve designs to minimize these environmental impacts, such as by incorporating noise-dampening materials and advanced dust collection systems.

In conclusion, small industrial metal shredders play an integral role in modern waste management strategies. They offer a solution that is both efficient and environmentally friendly, turning what is considered waste into a valuable resource. As technology advances and recycling becomes more imperative, the significance of these machines will continue to grow, highlighting their importance in our commitment to sustainable practices.

small industrial metal shredder. The recycled metal can be sold to foundries and manufacturing plants, generating income for recycling companies and fostering a circular economy. This approach not only conserves natural resources but also stimulates local economies by creating jobs within the recycling sector.

However, it is essential to consider the noise and dust emissions produced during the shredding process. Manufacturers continually strive to improve designs to minimize these environmental impacts, such as by incorporating noise-dampening materials and advanced dust collection systems.

In conclusion, small industrial metal shredders play an integral role in modern waste management strategies. They offer a solution that is both efficient and environmentally friendly, turning what is considered waste into a valuable resource. As technology advances and recycling becomes more imperative, the significance of these machines will continue to grow, highlighting their importance in our commitment to sustainable practices. Latest news

Troubleshooting Common Eddy Separator Problems

NewsJul.04,2025

The Role of Metal Recycling Plants in Circular Economy

NewsJul.04,2025

The Impact of Recycling Line Pickers on Waste Management Costs

NewsJul.04,2025

Safety Features Every Metal Shredder Should Have

NewsJul.04,2025

How Industrial Shredders Improve Waste Management Systems

NewsJul.04,2025

How Cable Granulators Contribute to Sustainable Recycling

NewsJul.04,2025