Jun . 25, 2024 09:06 Back to list

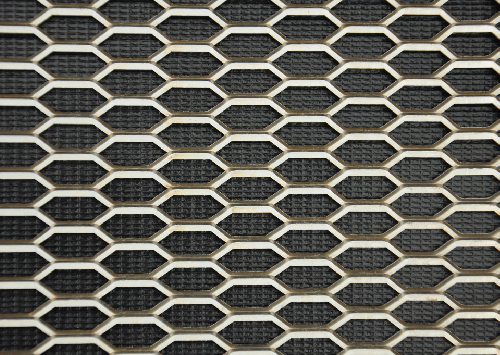

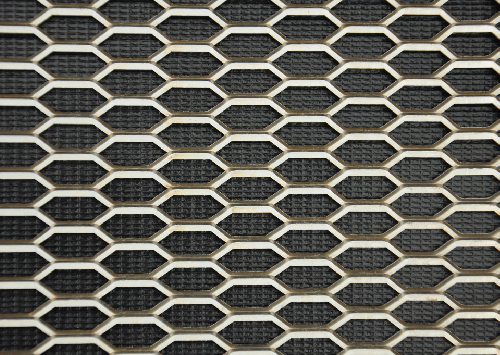

Manufacturers and scrap processors alike rely on these machines to transform bulky, space-occupying metal sheets into compact, easily transportable fragments

Manufacturers and scrap processors alike rely on these machines to transform bulky, space-occupying metal sheets into compact, easily transportable fragments

Manufacturers and scrap processors alike rely on these machines to transform bulky, space-occupying metal sheets into compact, easily transportable fragments

Manufacturers and scrap processors alike rely on these machines to transform bulky, space-occupying metal sheets into compact, easily transportable fragments sheet metal shredder. This transformation enhances storage options and reduces transportation costs, as the weight and volume of the metal are significantly decreased post-processing.

The technology behind the sheet metal shredder is continually advancing, with newer models featuring automated controls and safety systems that protect operators and enhance productivity. Modern sensors can detect variations in material density and adjust the shredding mechanism accordingly, ensuring efficient processing without compromising the integrity of the blades or the motor.

Moreover, the noise reduction and dust suppression features incorporated into contemporary designs have significantly improved the work environment around these machines, making them less of an auditory nuisance and reducing airborne particulate matter.

In conclusion, the sheet metal shredder is an exemplar of modern industrial machinery, combining brawn with brains to deliver a solution that is both ecologically sound and economically viable. As we move towards a future where sustainability and resource optimization become increasingly paramount, the sheet metal shredder remains a valuable asset in our quest for a balanced industrial ecosystem.

sheet metal shredder. This transformation enhances storage options and reduces transportation costs, as the weight and volume of the metal are significantly decreased post-processing.

The technology behind the sheet metal shredder is continually advancing, with newer models featuring automated controls and safety systems that protect operators and enhance productivity. Modern sensors can detect variations in material density and adjust the shredding mechanism accordingly, ensuring efficient processing without compromising the integrity of the blades or the motor.

Moreover, the noise reduction and dust suppression features incorporated into contemporary designs have significantly improved the work environment around these machines, making them less of an auditory nuisance and reducing airborne particulate matter.

In conclusion, the sheet metal shredder is an exemplar of modern industrial machinery, combining brawn with brains to deliver a solution that is both ecologically sound and economically viable. As we move towards a future where sustainability and resource optimization become increasingly paramount, the sheet metal shredder remains a valuable asset in our quest for a balanced industrial ecosystem. Latest news

Troubleshooting Common Eddy Separator Problems

NewsJul.04,2025

The Role of Metal Recycling Plants in Circular Economy

NewsJul.04,2025

The Impact of Recycling Line Pickers on Waste Management Costs

NewsJul.04,2025

Safety Features Every Metal Shredder Should Have

NewsJul.04,2025

How Industrial Shredders Improve Waste Management Systems

NewsJul.04,2025

How Cable Granulators Contribute to Sustainable Recycling

NewsJul.04,2025