Jun . 17, 2024 10:02 Back to list

On the other hand, the plastic insulation, though not as valuable as copper, can still be recycled and repurposed, reducing the overall waste stream On the other hand, the plastic insulation, though not as valuable as copper, can still be recycled and repurposed, reducing the overall waste stream

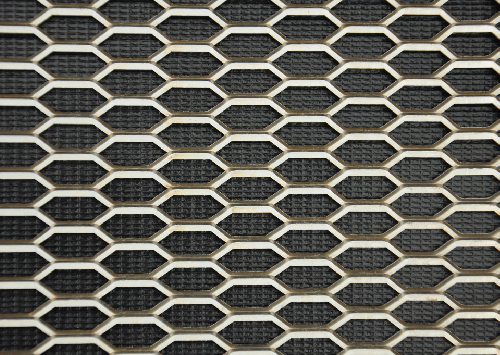

On the other hand, the plastic insulation, though not as valuable as copper, can still be recycled and repurposed, reducing the overall waste stream On the other hand, the plastic insulation, though not as valuable as copper, can still be recycled and repurposed, reducing the overall waste stream copper wire recycling machine.

Copper wire recycling machines play a crucial role in the circular economy, contributing to the reduction of raw material extraction and disposal of hazardous waste. Not only do they recover valuable metals, but they also help mitigate environmental pollution caused by improper waste disposal. Furthermore, they offer an economic benefit by providing a source of secondary raw materials for industries.

In light of the increasing global demand for copper and the need for sustainable waste management, investing in copper wire recycling technology is becoming more appealing. It is a testament to our commitment to responsible consumption and production, as outlined in the United Nations' Sustainable Development Goals.

In conclusion, copper wire recycling machines are a vital component in today's waste management and recycling landscape. They symbolize the potential of technology to transform waste into a resource, fostering a greener and more sustainable future. As we continue to innovate and improve these machines, their role in waste reduction and resource recovery will only become more significant.

copper wire recycling machine.

Copper wire recycling machines play a crucial role in the circular economy, contributing to the reduction of raw material extraction and disposal of hazardous waste. Not only do they recover valuable metals, but they also help mitigate environmental pollution caused by improper waste disposal. Furthermore, they offer an economic benefit by providing a source of secondary raw materials for industries.

In light of the increasing global demand for copper and the need for sustainable waste management, investing in copper wire recycling technology is becoming more appealing. It is a testament to our commitment to responsible consumption and production, as outlined in the United Nations' Sustainable Development Goals.

In conclusion, copper wire recycling machines are a vital component in today's waste management and recycling landscape. They symbolize the potential of technology to transform waste into a resource, fostering a greener and more sustainable future. As we continue to innovate and improve these machines, their role in waste reduction and resource recovery will only become more significant. Latest news

Troubleshooting Common Eddy Separator Problems

NewsJul.04,2025

The Role of Metal Recycling Plants in Circular Economy

NewsJul.04,2025

The Impact of Recycling Line Pickers on Waste Management Costs

NewsJul.04,2025

Safety Features Every Metal Shredder Should Have

NewsJul.04,2025

How Industrial Shredders Improve Waste Management Systems

NewsJul.04,2025

How Cable Granulators Contribute to Sustainable Recycling

NewsJul.04,2025