Jun . 15, 2024 09:47 Back to list

Scrap metal grinders also have economic implications

Scrap metal grinders also have economic implications

Scrap metal grinders also have economic implications

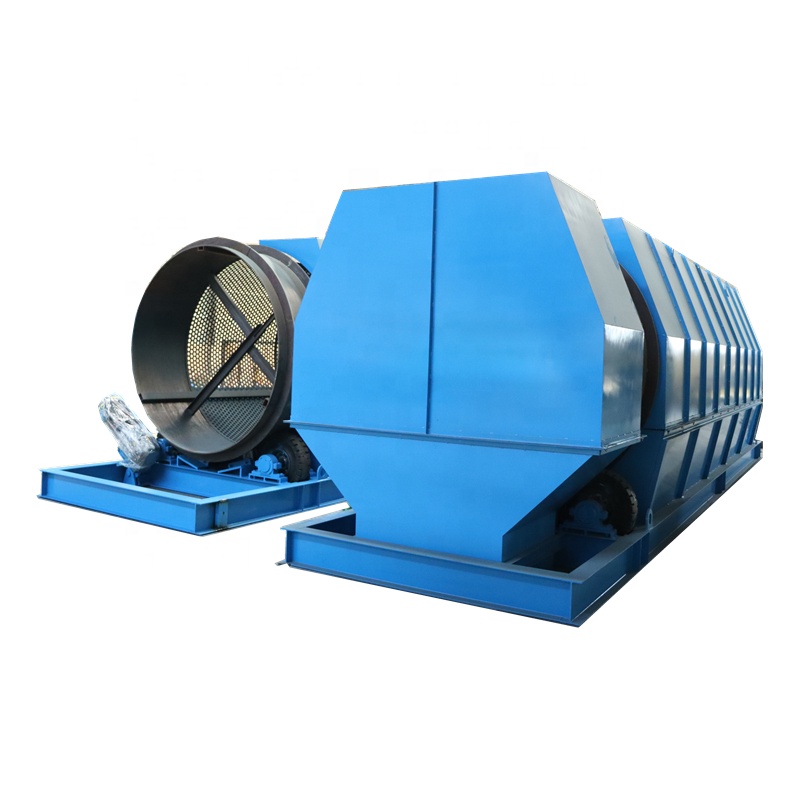

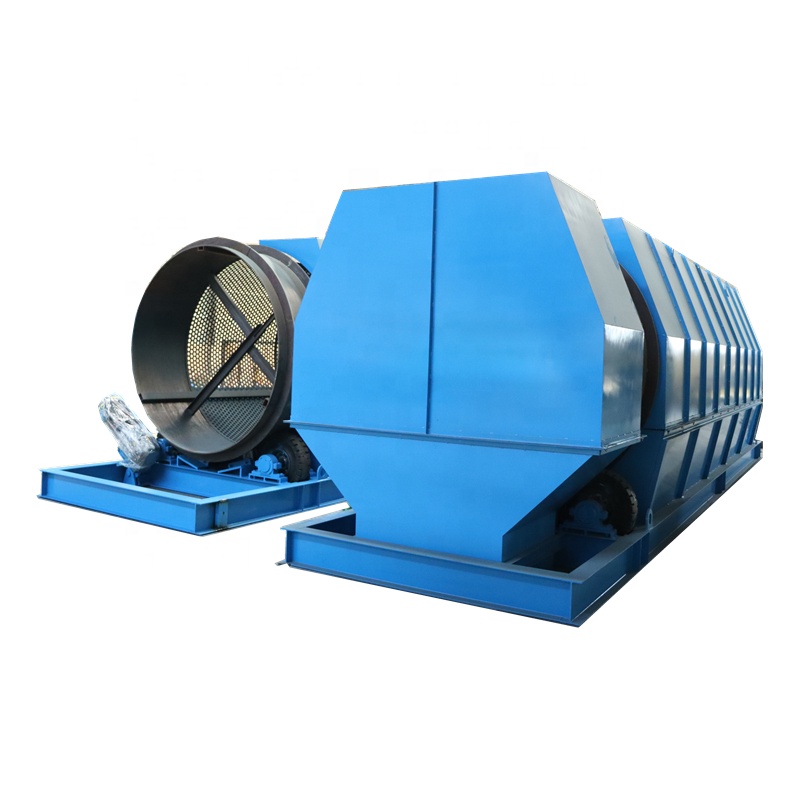

Scrap metal grinders also have economic implications scrap metal grinder. They help businesses in the scrap industry to maximize profits by increasing the volume of recyclable material they can process. Smaller metal fragments are easier to transport, store, and sell, lowering overall operational costs. Furthermore, the recycled metal has a consistent quality, ensuring its usability in various manufacturing processes.

Innovations in technology have led to the development of more efficient and specialized scrap metal grinders. Some modern models incorporate advanced features like magnetic separation systems to remove non-metallic contaminants, enhancing the purity of the recycled material. Others use intelligent control systems to optimize energy consumption and improve productivity.

In conclusion, scrap metal grinders are more than just machines; they are integral components of a sustainable waste management strategy. They facilitate the transition towards a circular economy by turning waste into a valuable resource, reducing environmental impact, and driving economic growth. As we continue to face global challenges related to waste disposal and resource depletion, the importance of scrap metal grinders in the recycling sector is expected to grow exponentially.

scrap metal grinder. They help businesses in the scrap industry to maximize profits by increasing the volume of recyclable material they can process. Smaller metal fragments are easier to transport, store, and sell, lowering overall operational costs. Furthermore, the recycled metal has a consistent quality, ensuring its usability in various manufacturing processes.

Innovations in technology have led to the development of more efficient and specialized scrap metal grinders. Some modern models incorporate advanced features like magnetic separation systems to remove non-metallic contaminants, enhancing the purity of the recycled material. Others use intelligent control systems to optimize energy consumption and improve productivity.

In conclusion, scrap metal grinders are more than just machines; they are integral components of a sustainable waste management strategy. They facilitate the transition towards a circular economy by turning waste into a valuable resource, reducing environmental impact, and driving economic growth. As we continue to face global challenges related to waste disposal and resource depletion, the importance of scrap metal grinders in the recycling sector is expected to grow exponentially. Latest news

Troubleshooting Common Eddy Separator Problems

NewsJul.04,2025

The Role of Metal Recycling Plants in Circular Economy

NewsJul.04,2025

The Impact of Recycling Line Pickers on Waste Management Costs

NewsJul.04,2025

Safety Features Every Metal Shredder Should Have

NewsJul.04,2025

How Industrial Shredders Improve Waste Management Systems

NewsJul.04,2025

How Cable Granulators Contribute to Sustainable Recycling

NewsJul.04,2025