Jun . 23, 2024 01:22 Back to list

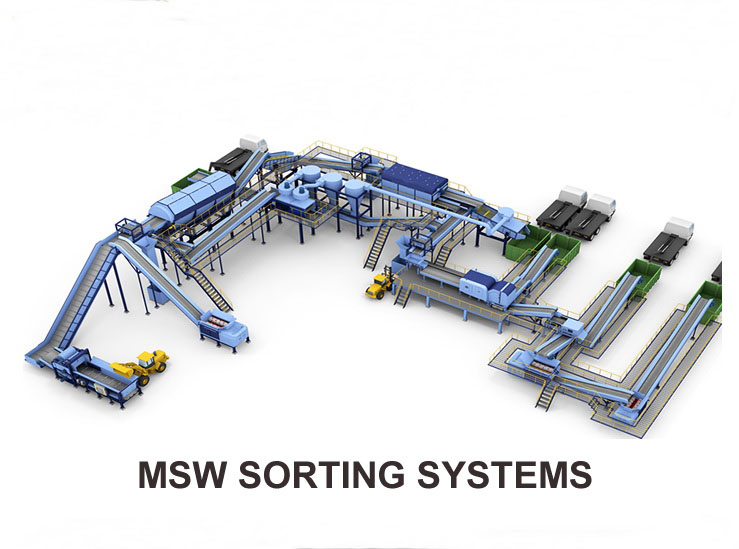

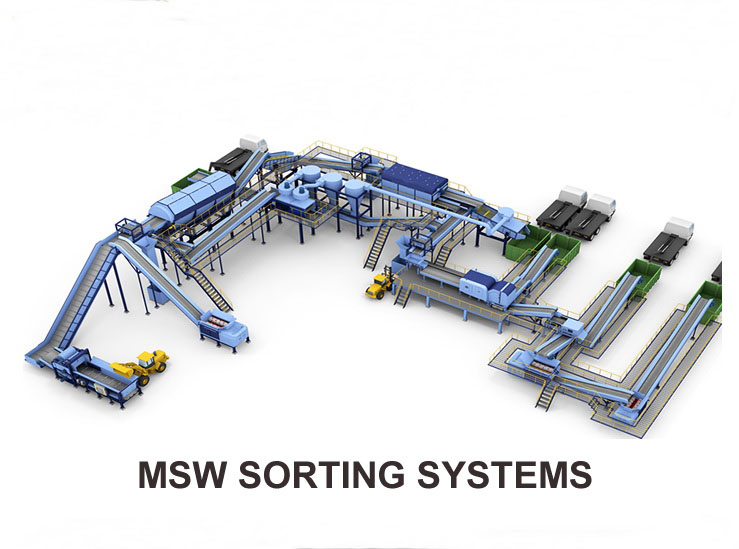

Eddy current separators find extensive application in various industries, including municipal solid waste management, scrap metal recycling, and even electronics waste processing

Eddy current separators find extensive application in various industries, including municipal solid waste management, scrap metal recycling, and even electronics waste processing

Eddy current separators find extensive application in various industries, including municipal solid waste management, scrap metal recycling, and even electronics waste processing

Eddy current separators find extensive application in various industries, including municipal solid waste management, scrap metal recycling, and even electronics waste processing eddy separator. They play a crucial role in recovering valuable metals like aluminum, copper, and brass, which can then be recycled and reused, contributing to sustainability efforts and reducing the reliance on virgin materials.

The efficiency and effectiveness of eddy current separators have led to their integration into modern recycling plants worldwide. They not only streamline the recycling process but also contribute to the global push towards a circular economy, where waste is minimized and resources are maximally utilized.

Moreover, advancements in technology have continuously improved the performance of eddy current separators. Innovations in magnetic design, belt materials, and control systems have enhanced their ability to separate smaller particles and increased the overall recovery rate of non-ferrous metals.

In conclusion, the eddy current separator, with its unique utilization of electromagnetic principles, is a game-changer in the world of waste management and recycling. Its ability to efficiently separate and recover valuable non-ferrous metals not only boosts economic viability but also significantly aids environmental conservation. As we move towards a more sustainable future, the importance of the eddy current separator in resource recovery will only continue to grow.

eddy separator. They play a crucial role in recovering valuable metals like aluminum, copper, and brass, which can then be recycled and reused, contributing to sustainability efforts and reducing the reliance on virgin materials.

The efficiency and effectiveness of eddy current separators have led to their integration into modern recycling plants worldwide. They not only streamline the recycling process but also contribute to the global push towards a circular economy, where waste is minimized and resources are maximally utilized.

Moreover, advancements in technology have continuously improved the performance of eddy current separators. Innovations in magnetic design, belt materials, and control systems have enhanced their ability to separate smaller particles and increased the overall recovery rate of non-ferrous metals.

In conclusion, the eddy current separator, with its unique utilization of electromagnetic principles, is a game-changer in the world of waste management and recycling. Its ability to efficiently separate and recover valuable non-ferrous metals not only boosts economic viability but also significantly aids environmental conservation. As we move towards a more sustainable future, the importance of the eddy current separator in resource recovery will only continue to grow. Latest news

The Future of Metal Recycling: Revolutionizing Waste Management

NewsMay.14,2025

Optimizing Waste with Recycling Lines

NewsMay.14,2025

Municipal Solid Waste Sorting Line: Revolutionizing Waste Management

NewsMay.14,2025

Metal Shredders: Essential Tools for Efficient Recycling

NewsMay.14,2025

Maximize Your Profits with a Copper Wire Granulator

NewsMay.14,2025

Home Metal Shredder: A Smart Choice for Your Home Recycling Needs

NewsMay.14,2025